Welcome to the Carbide Processors Blog

Profiling Router Bits- The Five Basic Shapes

Posted on Thursday, May 29th, 2014 at 10:17 am.

Profiling Router Bits are all about adding visible details using shadow and light to your projects: outer edge shaping, moldings, picture frames, cabinetry etc. A decorative edge can add considerable visual appeal, square edges are more common place, but it doesn’t have to be your first or last choice in edging. When these bits are used with a hand-held router, they will usually have a bearing on the end that follows the edge of the part and controls the cut depth.

Profiling Router Bits are all about adding visible details using shadow and light to your projects: outer edge shaping, moldings, picture frames, cabinetry etc. A decorative edge can add considerable visual appeal, square edges are more common place, but it doesn’t have to be your first or last choice in edging. When these bits are used with a hand-held router, they will usually have a bearing on the end that follows the edge of the part and controls the cut depth.

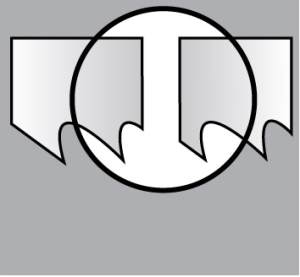

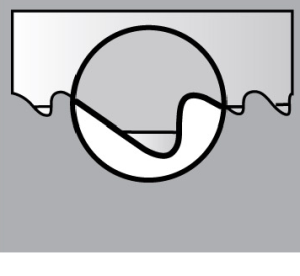

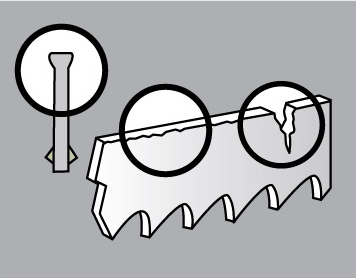

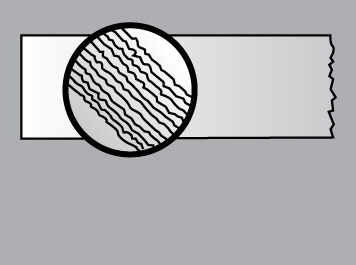

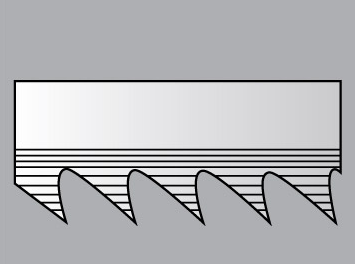

Almost every trim profile can be reduced to one of five basic shapes: chamfer, cove, round, bead and flute. (Note: The word ‘flute’ is also used to refer to the cutting edge of a router bit).

|

|

|

|

|

| Chamfer | Cove | Round | Bead | Flute |

Now these are just 5 of the most common profiling bits used, there are many more, not to mention the custom router bits (click here) that we make. If you just want to use what you have on hand you can use a combination of these to create several edge treatment possibilities. For example, combine a cove and a round over to rout a Roman Ogee or a bead and cove to rout a Classical Bead and Cove. In most cases you will find it easier to simply purchase the profile bit that best suits your application, individually or in a set.

Guiding the Bits

Edge profile bits must be accurately guided along the edge of the work piece for a controlled cut. You will find that a lot of edge-forming bits have a ball bearing guide mounted on the top of the bit (often referred to as piloted bits). These guides act as a fence as the bit rolls along the non-routed portion of the edge. This will only work when there is enough of a ledge for the ball bearing guide to ride on. When the entire edge of the piece is to be profiled then this edge will not be present and the bit cannot be guided by the bearing; these pieces will have to be routed using an external fence on the router base, or with a fence on the router table. As a general rule, when buying a router bit that is available with or without a guide bearing, choose the one that has a bearing.

A Bit of History

These basic shapes have defined various furniture styles throughout history. Originally these profiles were scraped or cut into the wood using sharpened metal blades. The blades were shaped with a negative of the desired profile by means of scratch sticks or beading tools, and then more elaborate hand planes. Industrial shaping of wood has been done using machines for well over a hundred and thirty years, but it wasn’t until the portable router became widely available in the 1970’s that the hobbyist woodworker had access to such powerful edge shaping capability (note that the design hasn’t changed).

To read more detailed information or ask your own questions using our Live Chat, visit our website.

And the SOG Knife Winners Are….

Posted on Wednesday, May 21st, 2014 at 1:41 pm.

The Free SOG Knife or Multi-Tool contest is officially over! We had a huge response to the free give-away, and we received helpful feedback on our newest line. If you didn’t know about it, check out our blog to read up on all the details. This was the first time we have ran a contest using Facebook; potential winners were asked to post comments on which SOG Knife or Multi-Tool they would most like to have based on our inventory. We made a video of us drawing the names out of a hat (you can watch the video) and then published it on YouTube.

And now for the winners….drum roll please….

Grand Prize Winner is: Larry Allred, he chose the SOG E37TN-CP

The 2 Runners Up were: Matt Sears and Philip Maszak, they had their choice of the SOG CrossCut or SOG Micron 2.0

SOG E37TN-CP is one of the most popular SOG items that we sell; it’s a high performance fixed blade tactical knife with a Titanium Nitride finish that is extremely resistant to scratches and peeling. It features a partially serrated blade with a clip point, and the handle has been re-designed for improved comfort.

SOG CrossCut 2.0 is a compact scissor multi-tool with 8 additional functions. The multiple pivot points allow the scissors to give twice the force of standard multi-tools for cutting. This tool is suitable for everyday personal care around the house or on the go.

SOG Micron 2.0 is a compact folding pocket knife suitable for a key chain or to carry around in your pocket. The blade is stainless steel with a bead blasted finish and features a smooth, non-serrated edge with a clip point; the handle

To see our full line of SOG Knives and Multi-Tools and to take advantage of huge savings click here to be directed to our webpage.

We had a great time reading all the comments and watching the participation intensify as the contest came to a close. The response was very valuable in letting us know what are customers want and are looking to buy. As I have said before in our blogs, the Carbide Processors, Inc. team put a lot of thought and effort in offering you quality products that you can afford, and by providing exceptional tools for the toughest applications.

Band Saw Troubleshooting

Posted on Wednesday, May 14th, 2014 at 10:04 am.

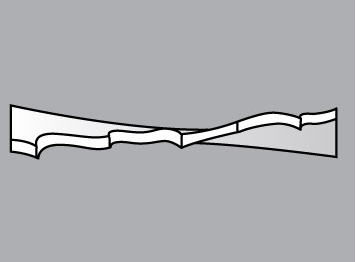

Common Band Saw problems and how to solve them. When it comes to learning what works and what doesn’t, nothing beats experience. MK Morse has over 45 years of experience in the Band Saw business. Over the years they have come across many different problems, and have discovered common causes and solutions. Below are 13 of the most common band saw problems including the cause and how to fix it. The information and pictures in this article are from the MK Morse catalog. Get a quote on a Morse Band Saw Blade made to fit your exact specifications.

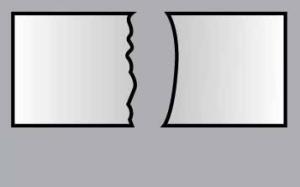

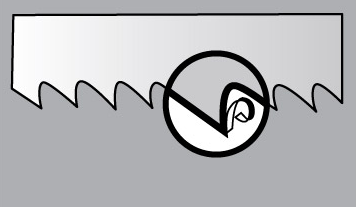

Problem 1: Premature Band Saw Blade Breakage- Straight break indicates fatigue.

Cause of the problem:

- Incorrect band saw blade- teeth too coarse

- Blade tension too high

- Side guides too tight

- Damaged or misadjusted band saw blade guides

- Excessive feed

- Incorrect cutting fluid

- Wheel diameter too small for band saw blade

- Band saw blade rubbing on wheel flanges

- Teeth in contact with work before starting saw

- incorrect blade speed

Solutions:

- Use finer tooth pitch

- Reduce band saw blade tension

- Check side guide clearance

- Check all guides for alignment/damage

- Reduce feed pressure

- Check coolant

- Use thinner blade

- Adjust wheel alignment

- Allow 1/2″ clearance before starting cut

- Increase or decrease blade speed.

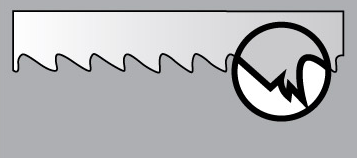

Problem 2: Premature Dulling of Teeth

Cause of the Problem:

- Teeth pointing in the wrong direction/ band saw blade mounted backwards

- Improper or no blade break-in

- Hard spots in material

- Material work hardened

- Improper coolant

- Improper coolant concentration

- Speed too high

- Feed too light

- Teeth too small

Solutions:

- Install band saw blade correctly. If teeth are facing the wrong direction, flip blade inside out.

- Break in blade properly (maintain proper blade speed for the material being cut). Reduce blade feed pressure or feed rate by 50% for the first 50 to 100 square inches of material cut. Gradually increase feed pressure or feed rate after break-in to target proper feed rate.

- Check for hardness, or hard spots like scale or flame cut areas

- Increase feed pressure or feed rate

- Check coolant type and coolant mixture

- Check recommended blade speed

- Increase feed pressure

- Increase tooth size

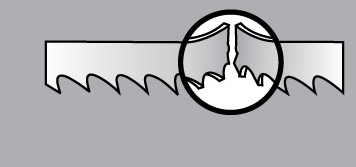

Problem 3: Inaccurate Cut

Cause of the Problem:

- Tooth set damage

- Excessive feed pressure

- Improper tooth size

- Cutting fluid not applied evenly

- Guides worn loose

- Insufficient blade tension

Solutions:

- Check for worn set on one side of blade

- Reduce feed pressure

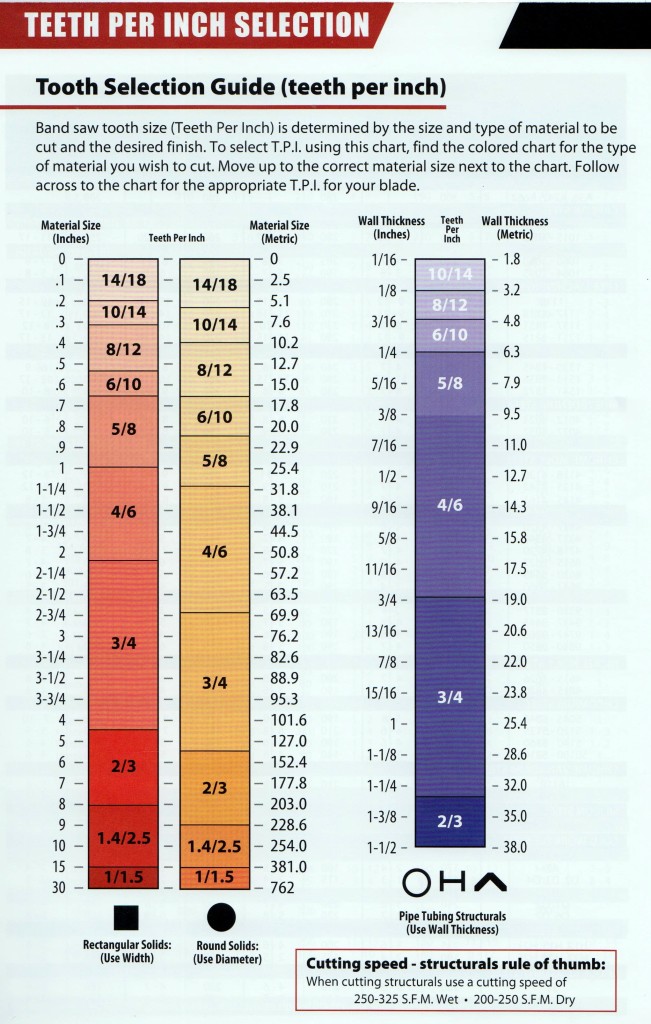

- Check Tooth size chart (Tooth Size chart)

- Check coolant nozzles

- Tighten or replace guides, check for proper alignment

- Adjust to recommended tension

Problem 4: Band Leading in Cut

Cause of the Problem:

- Over-feed

- Insufficient blade tension

- Tooth set damage

- Guide arms loose or set too far apart

- Chips not being cleaned from gullets

- Teeth too small

Solutions:

- Reduce feed force

- Adjust recommended tension

- Check material for hard inclusions

- Position arms as close to work as possible and tighten

- Check chip brush

- Increase tooth size

Problem 5: Chip Welding

Cause of the Problem:

- Insufficient coolant flow

- Wrong coolant concentration

- Excessive speed and/ or pressure

- Tooth size too small

- Chip brush not working

Solutions:

- Check coolant level and flow

- Check coolant ratio

- Reduce speed and/or pressure

- Use coarse tooth pitch

- Repair or replace chip brush

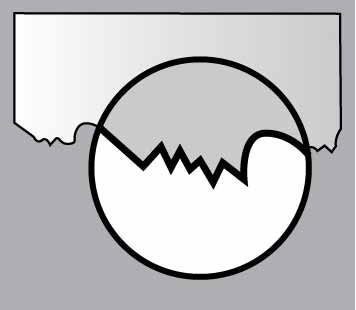

Problem 6: Teeth Fracture- Back of tooth indicates work spinning in clamps

Cause of the Problem:

- Incorrect speed and/or feed

- Incorrect blade pitch

- Saw guides not adjusted properly

- Chip brush not working

- Work spinning or moving in vise

Solutions:

- Check the cutting chart (cutting chart)

- Check tooth size chart (tooth size chart)

- Adjust or replace saw guides

- Repair or replace chip brush

- Check bundle configuration/adjust vise pressure

Problem 7: Irregular Break

Cause of the Problem:

- Indexing out of sequence

- Material loose in vice

Solutions:

- Check proper machine movement

- Check vise or clamp

Problem 8: Teeth Stripping

Cause of the Problem:

- Feed pressure too high

- Tooth stuck in cut

- Improper or insufficient coolant

- Incorrect tooth size

- Hard spots in material

- Work spinning in vise- lose nest or bundle

- Band saw blade speed too slow

- Blade teeth running backwards

- Chip brush not working

Solutions:

- Reduce feed pressure

- Do not enter old cut with a new blade

- Check coolant flow and concentration

- Check tooth size chart (tooth size chart)

- Check material for hard inclusions

- Check clamping pressure- be sure work is held firmly

- Increase blade speed- see (cutting chart)

- Reverse blade (turn inside out)

- Repair or replace chip brush

Problem 9: Wear on Back of Band Saw Blades

Cause of the Problem:

- Excessive feed pressure

- Insufficient blade tension

- Back-up guide roll frozen, damaged or worn

- Band saw blade rubbing on wheel flange

Solutions:

- Decrease feed pressure

- Increase blade tension and readjust guides

- Repair or replace back-up roll or guide

- Adjust wheel cant

Problem 10: Rough cut (Washboard surface, Vibration and or chatter)

Cause of the Problem:

- Dull or damaged blade

- Incorrect speed or feed

- Insufficient blade support

- Incorrect tooth pitch

- Insufficient coolant

Solutions:

- Replace with new blade

- Increase speed or decrease feed

- Move guide arms as close as possible to the work

- Use finer pitch band saw blade

- Check coolant flow

Problem 11: Wear Lines, Loss of set

Cause of the Problem:

- Saw guide inserts or wheel flange are riding on teeth

- Insufficient blade tension

- Hard spots in material

- Back-up guide worn

Solutions:

- Check machine manual for correct blade with

- Tension blade properly

- Check material for inclusions

- Replace guide

Problem 12: Twisted Blade- Profile Sawing

Cause of the problem:

- Blade binding in cut

- Side guides too tight

- Radius too small for blade width

- Work not firmly held

- Erratic coolant flow

- Excessive blade tension

Solutions:

- Decrease feed pressure

- Adjust side guide gap

- Use narrower blade

- Check clamping pressure

- Check coolant nozzles

- Decrease blade tension

Problem 13: Blade wear- Teeth Blued

Cause of the Problem:

- Incorrect band saw blade

- Incorrect feed or speed

- Improper or insufficient coolant

Solutions:

- Use coarser tooth pitch

- Increase feed or decrease speed

- Check coolant flow

Band Saw Blade Feed Speed

Posted on Tuesday, May 13th, 2014 at 3:18 pm.

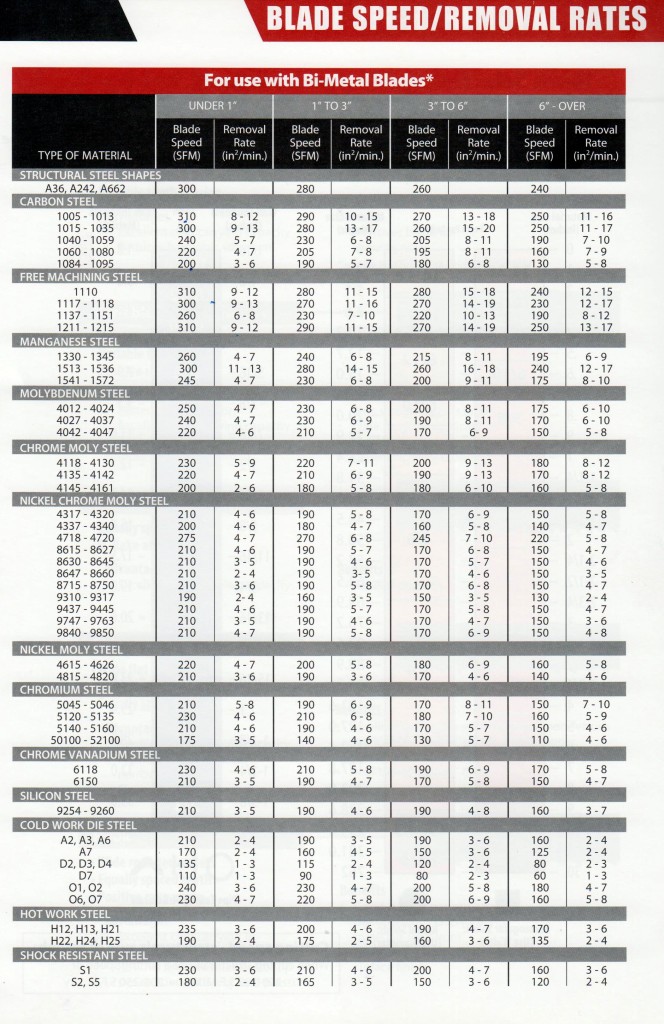

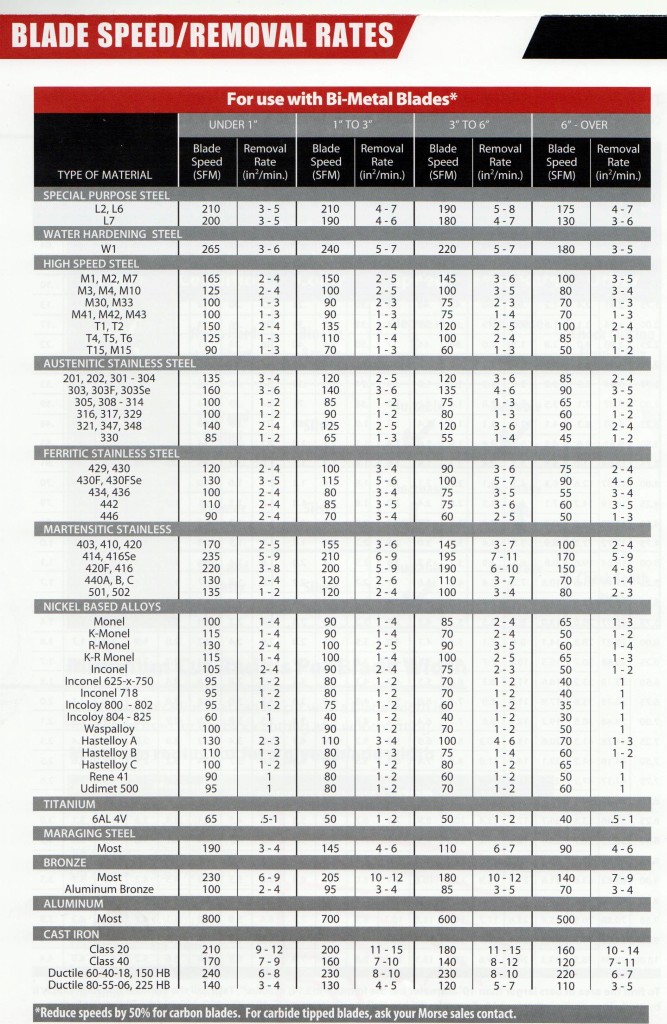

These Band Saw Blade Speed Feed rates are the recommended feed speed rates for the MK Morse band saw blades. For Carbon Band Saw Blades, it is recommended to reduce the speed rate by 50%. Get a quote on a Morse Band Saw Blade made to fit your specific application.

Win a Free SOG Knife!!

Posted on Monday, May 12th, 2014 at 3:50 pm.

Contest ends May 13, 2014

Well it’s finally here, your chance to win a FREE SOG Knife!!!!

We are running a contest and giving you the chance to win your favorite SOG Knife.

Contest starts May 13, 2014 and ends May 19, 2014.

Contest Rules:

The Grand Prize Winner will get to pick their Favorite SOG Knife from our Selection. Click here to see all the SOG knives and Multi-Tools we currently offer and pick your favorite one. Each Knife and Multi-Tool will have a comprehensive description of it’s function and specifications on our site. Once you’ve chosen (I know it will be hard), go to our Facebook page (here’s a link to it) and write your favorite SOG Knife in the comment field of the Free SOG give-away Post. That’s it, then you’ll be entered to win the SOG Knife of your dreams.

Carbide Processors isn’t just giving away one SOG Knife, there will also be SOG Knife prizes for the First Runner Up and Second Runner up. That’s right, after we pick our Grand Prize Winner, we will be awarding 2 more lucky contest participants their choice between a SOG CrossCut 2.0 Multi-Tool or the SOG Micron 2.0 folding Knife.

The SOG Knife give-away contest will be open from May 13th through May 19th. After May 19th, we will close the contest and pick the lucky winners. We will pick the winners using the most thorough and honest way we know how, by drawing names out of a hat! We will be recording the drawing and posting it on YouTube. Check out our Youtube channel and watch the drawing to see who the lucky winners are- One of the winners may be you. The video will be posted and winners announced on Tuesday, May 20th.

If you are a lucky winner, we will contact you via Facebook to get your shipping details.

Tell your friends, share the link to our website, post it to all your social media outlets, shout it from the mountain tops! Honestly, this is your opportunity to own a number one selling, high end, quality knife or multi-tool for FREE! For over 25 years SOG has offered innovative, dependable knives for hunting, combat, outdoor, and everyday use. The trusted choice by our military, and civil servants across the board.

Tell your friends, share the link to our website, post it to all your social media outlets, shout it from the mountain tops! Honestly, this is your opportunity to own a number one selling, high end, quality knife or multi-tool for FREE! For over 25 years SOG has offered innovative, dependable knives for hunting, combat, outdoor, and everyday use. The trusted choice by our military, and civil servants across the board.

We would really love to know what you think of your new SOG Knife or multi-tool. It’s yours to keep regardless, but we would really love to hear your opinion. Let us know the Good, the Bad, and the Ugly… no sugar coating it. Your posts will provide us with valuable feedback.

The Carbide Processors, Inc. team put a lot of thought into the needs of our customers when we introduce a new line. We don’t want to just make money (we do have bills to pay and a cute dog to feed), we want to provide exceptional tools for the toughest applications.

Filtration Systems and Supplies

Posted on Tuesday, May 6th, 2014 at 3:28 pm.

Would you buy a new car or truck and never change it’s oil? If you did change it’s oil, would you drive it without changing the filter? Filtering your machine coolant can improve quality of work in the shop, create a safer work environment, and reduce damage to equipment. Think of it as an insurance plan: it requires monthly attention (regular maintenance) but in the end, pays in $$$$$ (quality work).

To give you an idea of how dirty filters and cartridges can get after use, look at this side-by-side comparison!

Here is another example of how well these filter units work, you can easily see all the debris that fell out of the filter bag as I set it up next to a clean one. Filtering prevents these particles from damaging tools and equipment. It also saves a great deal of waste by drastically reducing the number of coolant changes and helps reduce the growth of bacteria.

I took these pictures yesterday using our work-table where we do the assembly of the filter units we sell on our webpage. Oh, you didn’t know that? Yes, with Tom’s assistance, us 3 ladies assemble, package and ship direct to you within 2 weeks of your order date. We follow exact specifications so every unit is assembled with the utmost care and accuracy! Here are a couple of units that we assemble-

I took these pictures yesterday using our work-table where we do the assembly of the filter units we sell on our webpage. Oh, you didn’t know that? Yes, with Tom’s assistance, us 3 ladies assemble, package and ship direct to you within 2 weeks of your order date. We follow exact specifications so every unit is assembled with the utmost care and accuracy! Here are a couple of units that we assemble-

The first picture is of a Wall Mount for Straight Oil with 20″ canisters; the second is a Wall Mount for Water Based or Straight Oils, with 10″ canisters; the last picture is of a Complete unit for Water or Oil based with a Coolant Pump. We have several for you to choose from, or we’ll develop a custom solution tailored specifically to your needs. Just let us know and we would be happy to supply you with a filter system, or supplies, to fit your needs.

The evolution of the pocket knife

Posted on Thursday, May 1st, 2014 at 8:57 am.

We have recently added SOG knives to our online store, and we LOVE them! The addition of SOG knives and the innovative changes in just the SOG product line have made me realize how far knives have come!

Folding Knives have come from a pretty humble beginning dating all the way back to 500 BC. The early pocket knives sure did not look like the SOG folding knives you may carry today. Pocket knives continued to advance and evolve over the years. Other functions were added to these pocket sized sidekicks, making them more versatile, and easier to use.

I came across an article that highlighted the history of the pocket knife. I’ve taken some facts and pics from the article to share. Here is a link to the original article- The History of the Pocket Knife.

The oldest pocket knife that has ever been discovered dates back to about 600-500 BC. It was discovered in Austria and consists of a single blade with a handle constructed out of bone.

The 1st Century Romans were also discovered to be avid pocket knife users. There were many bronze folding knives discovered from the Roman Empire during this era. The Roman’s folding knife used friction instead of springs to keep the blade locked tight away and required pressure from a hand or thumb to keep them open.

Multi Tools sure have come a long way. The Romans were the first to create a type of multi tool. The earliest multi tool discovered had a spoon, blade, spike, fork, spatula, and pick. It is believed to date back to around 200 and most likely belonged to a wealthy traveler.

Seeing them side by side, it’s easy to see the great advances in innovation, design and engineering between the early Roman multi Tool and this popular SOG multi tool.

Many folding knives have also been discovered from the Viking era. There were many friction folding knives similar to the 1st century Roman folding knives, but also many clasp knives that used a catch to hold the blade open. Now, most folding blades use springs and locks like the very popular Flash folding knife from SOG knives.

Here is a side by side to compare:

In the 1600, many more advances and designs of folding knives were becoming more popular. The pistol grip knife gained popularity in the early 1600s and was most likely used for fighting.

Between 1650 and 1700 the peasant knife or “penny knife” became very popular I England. It was much more affordable, allowing it to be more widely distributed especially among farmers and workers. The slipjoint knife also gained a lot of popularity during this time. The slipjoint knife featured a backspring that would keep the blade in the open position. This backspring design is what most pocket knives or folding knives still use today.

As the 1600’s came to an end and a new century was on the horizon, a few new designs in folding knives began to surface. The Navaja became popular in the late 1600’s and was a Spanish folding knife that operated similar to the penny knife in England. Much like the penny knife, the Navaja was most typically used by workers to do simple tasks like sharpening quills. The Navaja was different in that it was also used as a weapon. Years after it was popularized a locking device was added to the folding knife, making it one of the first folding knives with a locking mechanism.

The Butterfly pocket knife was also introduced in the early 1700s. Butterfly knives have two handles that conceal the blade until flipped around. The butterfly knife was typically used for self-defense or as a utility knife. SOG uses the same clever engineering of concealing the heart of the tool in the handle on many of their multi tools.

In the mid 1700’s the switch blade was introduced. The switchblade was known for their spring loaded blades that could be employed by a push of a button. The Stilleto was another switchblade style folding knife that was popularized in the mid 1900’s . Both switchblade style folding knives were often used for fighting or self-defense.

Various styles of folding knives surfaced and popularized throughout the 19th and 20th centuries. New innovative features were added making the folding knives more specialized for various uses. SOG consistently produces innovative styles of these vastly popular pocket companions that we have come to love over the years. SOG has created an extensive line of tactical knives, hunting knives, and knives and tools for the outdoor enthusiasts with superior engineering and cutting edge designs. It’s this kind of dedication to quality that has brought us great folding knives like SOG’s Flash II, and the Twitch II.

PSSSST…SOG Knives coming soon!!!

Posted on Monday, April 21st, 2014 at 3:29 pm.

Guess who is now offering award-winning, innovative knives for hunting, combat, outdoor, and everyday use? You guessed right, Carbide Processors! SOG Knives are known for their outstanding quality, workmanship, and attention to detail. You simply won’t find a better quality knife used by the every-day Joe, and our elite military heroes such as the Navy Seals and Special Forces units.

One other LITTLE secret just for our blog readers to know, we will be running a free SOG Knife special very, very soon! Don’t miss out on this great opportunity….more details to come!

Just a little way to say thank you to all our loyal and future customers!

The Heartbleed Bug

Posted on Tuesday, April 15th, 2014 at 2:12 pm.

I imagine many of you reading this have heard about the Heartbleed bug and are wondering which sites are affected and how it affects you.

The Heartbleed bug is not a virus, but simply an error in the coding in the open-source SSL that many sites use to protect their sensitive data. The heartbleed bug has affected nearly 2/3 of websites across the internet (our site, www.carbideprocessors.com, was not affected). Basically, Heartbleed is a vulnerability that centers around the encryption language computers use to keep information private. After checking to see if our website was affected and taking all necessary precautions, I did a little research to find out a little more about this little bug that has caused such a great and wide spread impact across the web world.

*Note: Carbide Processors’ site was not affected, but we would still advise you to change your passwords as it is a good practice for online security.

Fist let me explain a little more about what the heartbleed bug is. Basically Heartbleed is a bug in the OpenSSL which allows hackers to take chunks of information out of the server’s active memory by spoofing a “heartbeat”. “Active” really is the operative word here. With the Heartbleed vulnerability, hackers can only take information as it is being sent (so you would have to be sending the information at the exact same time the hacker is stealing the information). Basically, they can only intercept the data as it is being sent.

The biggest difference between this virus and a standard security breech where a server is hacked is that the information taken from a site that was affected by the heartbleed bug allows hackers to grab information that is not encrypted.

What is SSL?

If you ever log into a site that asks you for any personal information, you may notice a lock symbol and the “https://” in the browser. That means that information entered on that site is using a special encryption code to prevent hackers from being able to see your personal information. The SSL encrypts the sensitive information using a complex code. Many sites use what is called OpenSSL code to encrypt information. The Heartbleed bug is basically a security hole that was left open and allows hackers to eavesdrop on a communication between servers like when you login in or enter data on a site.

What should you do?

I have found this very handy tool that allows you to check websites to see if they have been affected or have fixed the problem on their websites. Even if the site shows as safe, you should definitely change your passwords. If the site has not fixed the coding error and is still showing as unsafe, do not login until they have fixed the problem and are no longer susceptible to the Heartbleed bug.

You can check websites at Filippo. There is a link below to the “Heartbleed test”:

https://filippo.io/Heartbleed/