MEGA Flux- New and improved brazing flux

What is flux and why use flux:

Flux is used for aiding in the brazing process. One of the main things that can cause a weak joint in brazing is impurities like particles, oils, dirt, or oxidation at the joint. Even if you clean the joint and remove any oils or dirt, the high tempatures required for brazing will cause the work piece and the silver solder to oxidize. Flux helps prevent oxidation during the brazing process. Many fluxes also have cleaning properties. You can read more about how flux is used for brazing in our “How to Braze” article.

The better the flux is the better your brazing reluts will be. Better flux typically has smaller particles in it as it has been filtered and processed more than standard black flux. It also has better cleaning properties.

We have been testing different fluxes since 1981 and Our new MEGA Flux is the best flux we have ever seen for brazing tungsten carbide. This flux cleans about 78% better than any other flux. This was a surface area test. We tested equal amounts by weight of Wolverine Black Flux, Carbide Processors Purified Flux and Carbide Processors Mega Flux. The Mega Flux cleaned 78% more area than either of the other fluxes.

With our New MEGA Flux you Will Get:

-

78% Better Cleaning

-

Much Better Bonding

-

Reduced Tip Loss on Saws

-

Reduced Breakage on all Tools

-

Easier Clean up

-

Easier Mixing

This Truly Is a Huge Improvement

We ran some production tests to see just how much better the MEGA Flux really was.

1. The first thing we noticed was that the flux had not separated as black flux does.

2. The next thing we noticed was how incredibly creamy, smooth the flux was.

3. We like to cut our flux with a little water for dispensing and the Mega Flux mixed beautifully. (You can also remix with water if it dries out.)

4. We tried the Mega Flux in a pretinning operation and the operator noticed that the Mega Flux did clean better.

5. The most important thing was that the braze alloy flow on the carbide saw tips was beautiful. There was an even flow to all four corners with no runover on the sides or the front of the carbide saw tips.

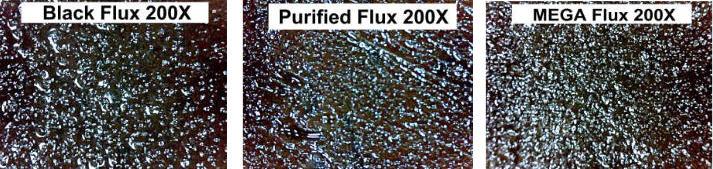

200 X pictures of the three brazing fluxes

Below are pictures of the three brazing fluxes magnified 200 times. The mega flux definitely has much smaller grains and there is a much greater consistency and homogeneity in the overall composition than with black flux or the purified flux.

Leave a Reply