5 Methods to Create Precise Rabbet Cuts

Here are 5 tried & true methods to creating the most precise Rabbet cuts! Rabbets can be cut with a table saw (set up with a dado set or combination blade), router (handheld or table mounted), or jointer. The choice depends on the type and quantity of work-pieces, and the desired quality of rabbet cut. (This except is taken from Wood Magazine 2011 edition)

** A rabbet is simply a rectangular recess along the edge or end of a work-piece. Although most often found as a joint in casework), a rabbet also can pop up as a design feature in a molding, as a recess for holding artwork in a picture frame, along the edges of a cabinet door to help recess it partway into its face frame, or as a half-lap or ship-lap joint.**

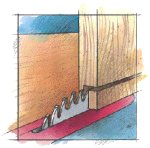

1. Table saw with a dado set: We use this setup often because it yields clean rabbets in one pass typically-two passes for wide rabbets. For good results, you need a high-quality dado set. Since it takes a little time to install the dado blades, we use this method only if we have several work-pieces to cut.

- Attach a 3/4″ wooden face to your table saw fence. By doing this you can cut into the wooden face and fine-tune the width of the rabbet with quick fence adjustments.

2. Table saw with standard blade: If we’re rabbeting just a piece or two, we’ll leave our combination blade in the table saw and make the cut in two passes. The key: You need to precisely set the fence, and the height of the blade, for both cuts so one doesn’t cut beyond the other.

- Cut the rabbet to its correct depth with the work-piece face down on the tabletop. Then, stand the piece on edge to cut the rabbet to width.

- If you don’t own a good dado set, or have a low-powered saw, this option may prove better than No. 1 for all of your work. But, it can be tricky if you need to rabbet the end of a narrow workpiece. In that case, you will need to clamp the work-piece to a fixture that holds it steady and upright as you guide it along the fence.

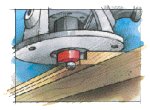

3. Handheld router with rabbeting bit. Unlike saw blades and dado sets, router bits do not leave tiny scoring marks. So, use a router bit if the surface or ends of the rabbets will be visible in your finished project.

- Router bits are your only option if you need to rabbet an opening inside a surface rather than along an outside edge or end. Examples include a router-table opening for receiving a router plate, or the inside of an assembled door frame for accepting a piece of glass.

-

With a handheld router you typically use a rabbeting bit with a pilot bearing as shown above. You can change the width of the cut simply by changing bearings. And, with this setup you can even cut rabbets along curved edges.

4. Router table with a straight bit. Although you can’t easily rabbet large pieces on a router table, this method has some distinct advantages over a handheld router. First, a router table has a fence that ensures a perfectly straight rabbet (a bearing-piloted bit will follow any irregularities in the work-piece edge). And, although a piloted rabbeting bit will help you cut a rabbet up to 1/2″ wide and 1/2″ deep, you can put a large straight bit in a router table and cut rabbets up to 1X1″.

5. Jointer: We admit we rarely use a jointer to cut rabbets, but if you must cut a perfectly smooth rabbet over 1″ wide, and along a straight, outside edge, look to a jointer. You can cut a rabbet as wide as the length of your jointer’s cutterhead. The maximum cutting depth of your jointer will limit the depth of the rabbet, typically to 1/2″.

- To do this, you need to make an initial cut with your table saw. First, set the blade height to match the depth of the rabbet. Adjust the fence-to-outside-of-blade distance to match the rabbet width. As shown, this cut will prevent the end of the jointer’s knives from hammering the work-piece. Remove no more than 1/8″ with each jointer pass.

Using these tips and tricks should help you to be successful in cutting the cleanest & smoothest rabbet cuts!

Leave a Reply