Band Saw Troubleshooting

Common Band Saw problems and how to solve them. When it comes to learning what works and what doesn’t, nothing beats experience. MK Morse has over 45 years of experience in the Band Saw business. Over the years they have come across many different problems, and have discovered common causes and solutions. Below are 13 of the most common band saw problems including the cause and how to fix it. The information and pictures in this article are from the MK Morse catalog. Get a quote on a Morse Band Saw Blade made to fit your exact specifications.

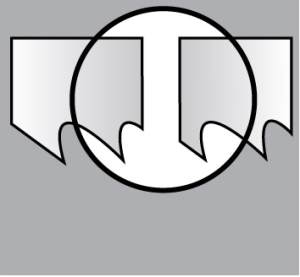

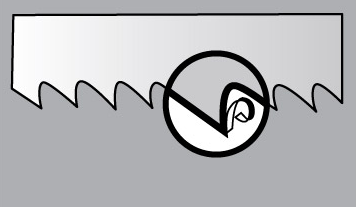

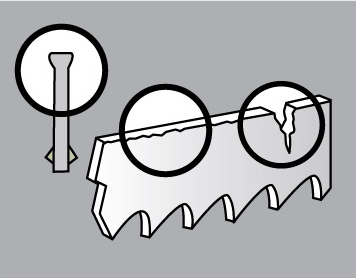

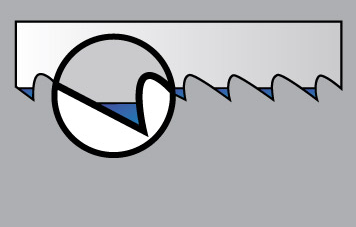

Problem 1: Premature Band Saw Blade Breakage- Straight break indicates fatigue.

Cause of the problem:

- Incorrect band saw blade- teeth too coarse

- Blade tension too high

- Side guides too tight

- Damaged or misadjusted band saw blade guides

- Excessive feed

- Incorrect cutting fluid

- Wheel diameter too small for band saw blade

- Band saw blade rubbing on wheel flanges

- Teeth in contact with work before starting saw

- incorrect blade speed

Solutions:

- Use finer tooth pitch

- Reduce band saw blade tension

- Check side guide clearance

- Check all guides for alignment/damage

- Reduce feed pressure

- Check coolant

- Use thinner blade

- Adjust wheel alignment

- Allow 1/2″ clearance before starting cut

- Increase or decrease blade speed.

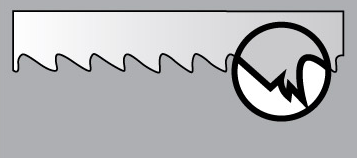

Problem 2: Premature Dulling of Teeth

Cause of the Problem:

- Teeth pointing in the wrong direction/ band saw blade mounted backwards

- Improper or no blade break-in

- Hard spots in material

- Material work hardened

- Improper coolant

- Improper coolant concentration

- Speed too high

- Feed too light

- Teeth too small

Solutions:

- Install band saw blade correctly. If teeth are facing the wrong direction, flip blade inside out.

- Break in blade properly (maintain proper blade speed for the material being cut). Reduce blade feed pressure or feed rate by 50% for the first 50 to 100 square inches of material cut. Gradually increase feed pressure or feed rate after break-in to target proper feed rate.

- Check for hardness, or hard spots like scale or flame cut areas

- Increase feed pressure or feed rate

- Check coolant type and coolant mixture

- Check recommended blade speed

- Increase feed pressure

- Increase tooth size

Problem 3: Inaccurate Cut

Cause of the Problem:

- Tooth set damage

- Excessive feed pressure

- Improper tooth size

- Cutting fluid not applied evenly

- Guides worn loose

- Insufficient blade tension

Solutions:

- Check for worn set on one side of blade

- Reduce feed pressure

- Check Tooth size chart (Tooth Size chart)

- Check coolant nozzles

- Tighten or replace guides, check for proper alignment

- Adjust to recommended tension

Problem 4: Band Leading in Cut

Cause of the Problem:

- Over-feed

- Insufficient blade tension

- Tooth set damage

- Guide arms loose or set too far apart

- Chips not being cleaned from gullets

- Teeth too small

Solutions:

- Reduce feed force

- Adjust recommended tension

- Check material for hard inclusions

- Position arms as close to work as possible and tighten

- Check chip brush

- Increase tooth size

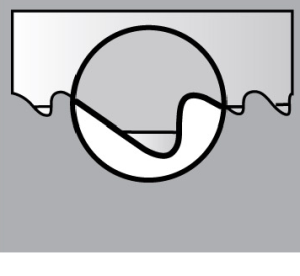

Problem 5: Chip Welding

Cause of the Problem:

- Insufficient coolant flow

- Wrong coolant concentration

- Excessive speed and/ or pressure

- Tooth size too small

- Chip brush not working

Solutions:

- Check coolant level and flow

- Check coolant ratio

- Reduce speed and/or pressure

- Use coarse tooth pitch

- Repair or replace chip brush

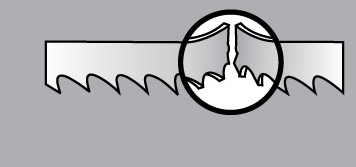

Problem 6: Teeth Fracture- Back of tooth indicates work spinning in clamps

Cause of the Problem:

- Incorrect speed and/or feed

- Incorrect blade pitch

- Saw guides not adjusted properly

- Chip brush not working

- Work spinning or moving in vise

Solutions:

- Check the cutting chart (cutting chart)

- Check tooth size chart (tooth size chart)

- Adjust or replace saw guides

- Repair or replace chip brush

- Check bundle configuration/adjust vise pressure

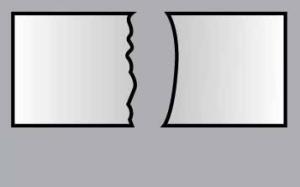

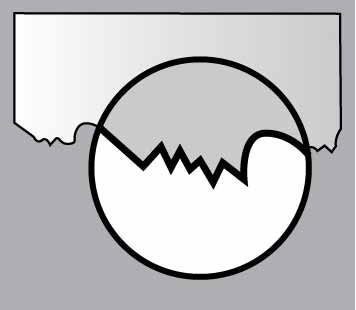

Problem 7: Irregular Break

Cause of the Problem:

- Indexing out of sequence

- Material loose in vice

Solutions:

- Check proper machine movement

- Check vise or clamp

Problem 8: Teeth Stripping

Cause of the Problem:

- Feed pressure too high

- Tooth stuck in cut

- Improper or insufficient coolant

- Incorrect tooth size

- Hard spots in material

- Work spinning in vise- lose nest or bundle

- Band saw blade speed too slow

- Blade teeth running backwards

- Chip brush not working

Solutions:

- Reduce feed pressure

- Do not enter old cut with a new blade

- Check coolant flow and concentration

- Check tooth size chart (tooth size chart)

- Check material for hard inclusions

- Check clamping pressure- be sure work is held firmly

- Increase blade speed- see (cutting chart)

- Reverse blade (turn inside out)

- Repair or replace chip brush

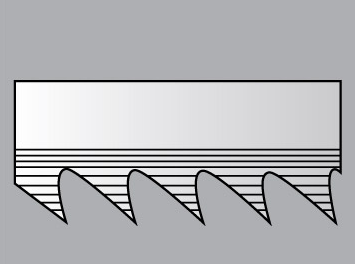

Problem 9: Wear on Back of Band Saw Blades

Cause of the Problem:

- Excessive feed pressure

- Insufficient blade tension

- Back-up guide roll frozen, damaged or worn

- Band saw blade rubbing on wheel flange

Solutions:

- Decrease feed pressure

- Increase blade tension and readjust guides

- Repair or replace back-up roll or guide

- Adjust wheel cant

Problem 10: Rough cut (Washboard surface, Vibration and or chatter)

Cause of the Problem:

- Dull or damaged blade

- Incorrect speed or feed

- Insufficient blade support

- Incorrect tooth pitch

- Insufficient coolant

Solutions:

- Replace with new blade

- Increase speed or decrease feed

- Move guide arms as close as possible to the work

- Use finer pitch band saw blade

- Check coolant flow

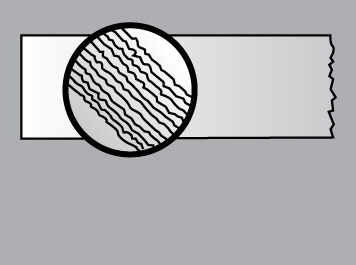

Problem 11: Wear Lines, Loss of set

Cause of the Problem:

- Saw guide inserts or wheel flange are riding on teeth

- Insufficient blade tension

- Hard spots in material

- Back-up guide worn

Solutions:

- Check machine manual for correct blade with

- Tension blade properly

- Check material for inclusions

- Replace guide

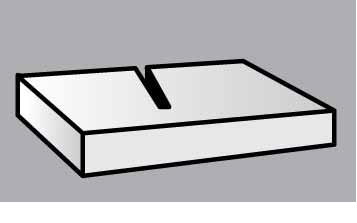

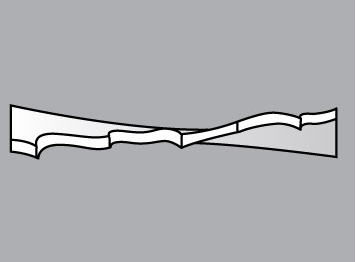

Problem 12: Twisted Blade- Profile Sawing

Cause of the problem:

- Blade binding in cut

- Side guides too tight

- Radius too small for blade width

- Work not firmly held

- Erratic coolant flow

- Excessive blade tension

Solutions:

- Decrease feed pressure

- Adjust side guide gap

- Use narrower blade

- Check clamping pressure

- Check coolant nozzles

- Decrease blade tension

Problem 13: Blade wear- Teeth Blued

Cause of the Problem:

- Incorrect band saw blade

- Incorrect feed or speed

- Improper or insufficient coolant

Solutions:

- Use coarser tooth pitch

- Increase feed or decrease speed

- Check coolant flow

Tags: bandsaw blades, bandsaw problems, bandsaws, cutting problems, troublshooing bandsaws

3 Responses to “Band Saw Troubleshooting”

Leave a Reply

Many problems that i always meet, it’s a very helpful topic!

Amazing article, article is explained in a good way and with images, it makes easy for us to understand this article.

Great troubleshooting guide! Thanks!