Truing a Square

Using a woodworking square is essential to creating quality woodworking projects, but what if your square is not true? We found this very helpful article from the book Handy Farm Devices and How to Make Them by: R. Cobleigh, about How to True a Square.

We currently sell Woodpeckers Woodworking Squares, and find them to be the highest quality, Truest Squares you can find. I’d love to hear any comments from anyone who owns one and wants to try this technique out to test their Woodpeckers Square.

Truing a Square

Making a Straight Edge:

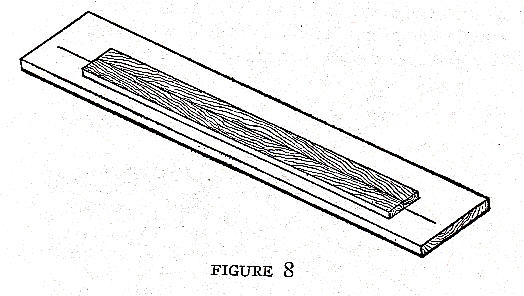

In connection with the work with the steel square a straight-edged board is necessary to have ready for immediate use. Procure a board 8 or 10 feet long of good, dry pine, free from knots and 6 to 8 inches wide. Plane the edge until it seems straight to the eye, then lay it on the bench or on another board and make a mark along the edge, just straight with a fine lead pencil; reverse it or turn it over and fit it to the other side of the pencil line.

This multiplies any inaccuracy or deviation from a straight line. Make a new line each time you plane the edge. Work with as long a plane as you have and set the blade to take a fine shaving. When the edge will fit both sides of the line made from it while in one position, it is straight. Figure 8 will give a clear idea of this operation.

Truing The Square

After obtaining a steel square, the first and most essential thing is to test or prove it to see that it is accurate, forming the angle of a perfect square.

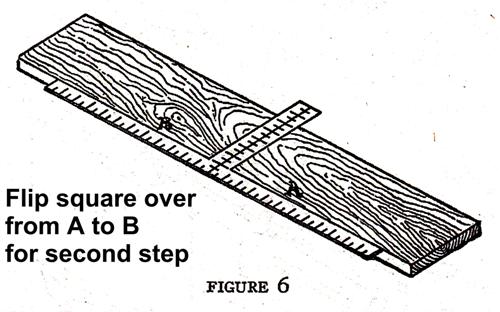

Take a board planed on one side and straighten one edge of it perfectly as described under ‘Making a Straight Edge’. Make a mark across this board with the square, as shown then reverse the square to Position B. If the square is true it should exactly fit the mark made. It is necessary to work very accurately, making the mark with the point of knife and having the edge of the board absolutely straight.

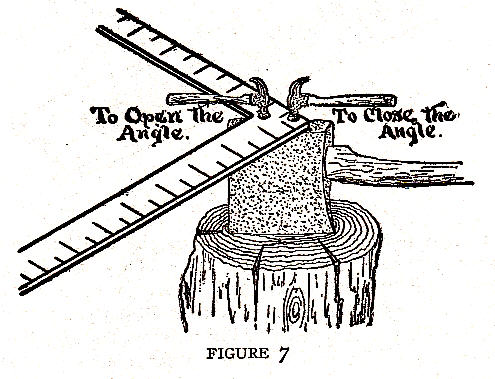

If the square is found to be out or inaccurae, it is not necessary to throw it away; it can be made true by a simple method by any handy mechanic. If you do not possess an anvil, make a substitute by sticking the ax into the chopping block, lay the square on the head on the head of the ax so that bearing will come from the throat or inside angle to the heel or outside of the square. To close up the angle, strike with a hammer a sharp blow at a point near the heel; to open the angle, strike near the throat at a point indicated in fig. 7. Don’t strike too hard. Use a bell face nail hammer and the dent will not be noticed

The Rule Of 6, 8 And 10

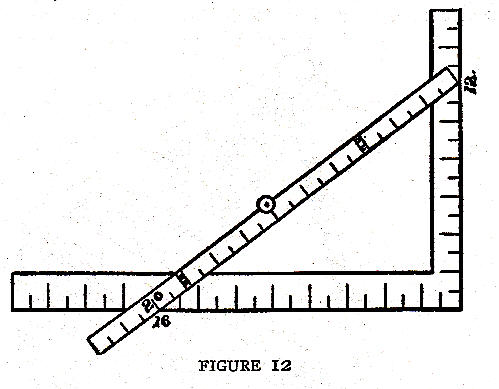

This is a rule so extensively used in the building trades and others that it has finally come to be known by the above name. It is derived from the 47th Problem of Euclid, and is used in the manner shown in Figure 13.

Measure 6 feet on the end sill of a building and 8 feet on the side sill. If it measures 10 feet across the angle the building is square. This is a very useful rule and easily remembered.

Leave a Reply