Why Are There So Many Router Bits?

If you have ever done any type of wood work you have encountered the wide world of router bits. Router bits range in shape, size, style and vary depending on application; when you visit the local store you will see them, almost identical looking stacked neatly side by side, a virtual sea of all shapes and sizes, and somewhere in there is the router bit you need. I won’t be able to cover every type of router bit there is, but I will cover the most common. Here is a crash course or refresher in what each router bit is used for:

If you have ever done any type of wood work you have encountered the wide world of router bits. Router bits range in shape, size, style and vary depending on application; when you visit the local store you will see them, almost identical looking stacked neatly side by side, a virtual sea of all shapes and sizes, and somewhere in there is the router bit you need. I won’t be able to cover every type of router bit there is, but I will cover the most common. Here is a crash course or refresher in what each router bit is used for:

Quality over Cheapest

Good quality router bits are sharp, and stay sharp for a long time (with proper use). They are well balanced and create minimal vibration; they are designed for excellent cutting geometry and have excellent chip ejection properties (work comes to a standstill because of chip buildup).

Most woodworkers prefer carbide tipped router bits because they can hold their edge between 10 and 25 times as long as high speed steel bits. They are also made of high quality, fine grained carbide, which allows for a sharper cutting edge.

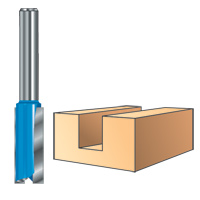

Straight Router Bit

Straight router bits are among the most common frequently used of all bits. Straight bits are used to make cuts straight down into a material to form a groove, dado or to hollow out an area for a mortise or inlay. Straight bits come in a variety of cut diameters, most commonly in the range from 3/16″ to 1-1/2″.

Straight router bits are among the most common frequently used of all bits. Straight bits are used to make cuts straight down into a material to form a groove, dado or to hollow out an area for a mortise or inlay. Straight bits come in a variety of cut diameters, most commonly in the range from 3/16″ to 1-1/2″.

Rabbeting Router Bit

Rabbeting router bits produce a straight vertical and horizontal cut, and are designed specifically to cut a rabbet (notch) in the edge of a material. These bits are an example of a “piloted” router bit, meaning that a bearing at the top of the bit is used to guide along the edge of the material. Rabbeting bits usually come in a set that includes a range of pilot bearing diameters, allowing a single bit to produce a variety of rabbet dimensions.

Rabbeting router bits produce a straight vertical and horizontal cut, and are designed specifically to cut a rabbet (notch) in the edge of a material. These bits are an example of a “piloted” router bit, meaning that a bearing at the top of the bit is used to guide along the edge of the material. Rabbeting bits usually come in a set that includes a range of pilot bearing diameters, allowing a single bit to produce a variety of rabbet dimensions.

Flush Trim Router Bit

Flush trim router bits are guided by a pilot bearing that is the same size as the bit’s cutting radius. They’re used to trim the edge of one material flush with the edge of another material. Trimming a veneered surface flush with a substrate, or using a pattern to create multiple identical shapes are examples. The pilot bearing may be on the top of the bit, the base of the cutting edge, or both.

Flush trim router bits are guided by a pilot bearing that is the same size as the bit’s cutting radius. They’re used to trim the edge of one material flush with the edge of another material. Trimming a veneered surface flush with a substrate, or using a pattern to create multiple identical shapes are examples. The pilot bearing may be on the top of the bit, the base of the cutting edge, or both.

Chamfer Router Bit

Chamfer router bits are designed to cut the edge of a part or panel at an angle. They are also can be used in joinery to create beveled edges for multi-sided constructions.

Chamfer router bits are designed to cut the edge of a part or panel at an angle. They are also can be used in joinery to create beveled edges for multi-sided constructions.

Edge Forming Router Bit

Edge forming router bits are most often used to cut a decorative edge into a material. Many edge forming bits include a pilot bearing. In most cases, the bits are used for final decoration of a project where edges are already established and can serve as the guide for the bit. A few examples of edge forming router bits are: Ogee router bit which refers to the “S” shaped profile; Round over bit which is used to cut a rounded edge of a given radius.

Edge forming router bits are most often used to cut a decorative edge into a material. Many edge forming bits include a pilot bearing. In most cases, the bits are used for final decoration of a project where edges are already established and can serve as the guide for the bit. A few examples of edge forming router bits are: Ogee router bit which refers to the “S” shaped profile; Round over bit which is used to cut a rounded edge of a given radius.

Molding Router Bit

Designed for architectural molding profiles, molding bits are typically larger than basic edge forming router bits. Molding bits may incorporate multiple basic edge forming profiles into a single router bit. Because of their size, molding router bits most safely used in a router table.

Designed for architectural molding profiles, molding bits are typically larger than basic edge forming router bits. Molding bits may incorporate multiple basic edge forming profiles into a single router bit. Because of their size, molding router bits most safely used in a router table.

Visit our website for more detailed information to help you choose the right router bit for your next project.

Tags: carbide router bits, moulding router bits, rabbet bits, router bits, straight router bits, woodworking

Leave a Reply