How to Choose Wood

A piece of wood that warps, bows, cups or twists can ruin a project. If the wood dries unevenly, it can cause uneven shrinkage or swelling. Being aware of what may cause the wood to shrink or swell unevenly can help save your woodworking projects. There are some ways to avoid or help reduce the chances of your wood warping, bowing or twisting.

Plywood or other manufactured wood is far less likely to shrink or swell as a result of too much moisture in wood. It can be a good alternative if you want to avoid the possibility of uneven moisture related movement of your project wood.

If you plan on using hard or soft wood, you can still do things to help reduce the chances of your Lumber being ruined from uneven shrinking or swelling. It helps to understand why the wood does this in the first place.

What causes uneven shrinkage in wood stock:

Before a tree is cut down for lumber, the wood is basically a series of thin tubes that bring sap and fluids from the tree’s roots to the upper branches. There is more sap and fluid being brought up through the wood in the outer parts of the tree trunk than toward the center. Lumber that is cut from the heartwood (the wood closest to the center of the tree) is less likely to shrink or swell than the wood that is cut from the sapwood (wood from the outer portion of the tree trunk).

This means that the wood cut from the heartwood will be far less likely to shrink or swell than the Sapwood because the heartwood is less likely to retain moisture.

Shrinkage differs based on the dimensions of the wood:

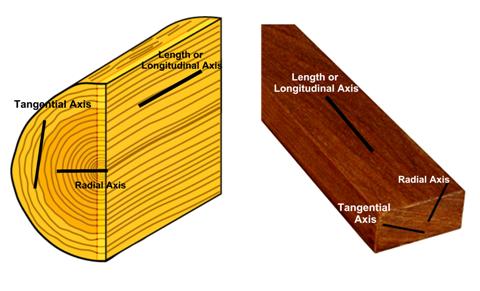

The shrinkage along the length of the lumber is far less than the shrinkage along the radius axis or tangential axis of the wood stock. If you are looking at the end grain of the wood, the radius is the direction perpendicular to the growth rings and the tangent is parallel to the growth rings. The greatest shrinkage almost always occurs along the tangential axis of the wood stock. You can sort of guess whether the board will cup, twist or bow based on the direction of the growth rings on the grain and by how much or if the tangential movement exceeds the radial movement.

Reducing shrinkage by acclimating the wood:

Wood definitely needs to be dried properly before using it for any woodworking project, but it can also make a big difference to allow the wood to be acclimated to the environment the finished project will be in. For example, if the wood stock comes from a very humid environment, removing it from that environment and using it to build a project in a very dry climate can cause additional shrinkage in the wood and greatly affect your finished work.

If you purchase the wood and store it in the location where your finished project will be before beginning your project, it can greatly reduce the chances of the wood shrinking or swelling after the project is completed.

About.com Tip “Movement is one of the many reasons why quarter-sawn lumber is so sought after (and expensive). Because of the way quarter-sawn wood is hewn from a log, the growth rings are relatively square to the sides of the board. As such, the board will swell or shrink relatively evenly across the entire board.”

Tips for choosing stock:

Knowing how wood shrinks or swells can help you decide what wood to use for your woodworking projects, and to better account for wood that may cup or twist. For example: if you’re gluing up a table-top from a series of tangentially-cut boards, you’re likely to experience some cupping as the wood swells or shrinks. Knowing this allows you to address the situation. If a number of the boards look as though they may experience similar cupping, you can flip every other board upside down so that they alternate cupping upwards and downwards. Doing this can prevent your table top from having a large bow in the center.

Another thing to look out for is the distance between the growth rings. Choose wood with rings that are closer together, as they have less uneven movement. A tangentially-cut board with wide growth rings can have much more uneven movement, and can even result in cracking (called checking) if the cupping becomes excessive.

Also, sealing the end of your lumber with paint of a sealant can help prevent shrinkage or swelling of the wood.

Tags: choosing lumber, lumber, wood shrinkage

One Response to “How to Choose Wood”

Leave a Reply

I always leave the hard wood inside the shop up high in the heat of the room with a wood stick every 16 to 18 inches on the plank and then a other plank on top of that one for air drying 8 years or so.

just make sure that the stick is the same size and type of wood as the plank !!!!