Inspecting saw blades- Side Clearance

When looking for a saw blade, it can be difficult to know how to choose a saw blade and what to look for to know if you are really getting a good quality saw blade. There are many aspects to a saw blade that will affect the longevity of the blade and the quality of the cut. One aspect of the saw blade that often gets overlooked, but does affect the quality of the blade and cut to a pretty high degree is the side clearance.

Side clearance is a measure of how far the side of the saw tips stick out from the side of the saw blade. Ideally side clearance would be the same for every saw tip although this is not the way it usually works.

Side clearance can make a huge difference in how well the saw blade cuts. If you have some teeth sticking out more than others the teeth that stick out will leave the arcs in the cut wood that everybody recognizes and nobody likes.

We do not sell any saw blades where the side clearance variances more than one half of 1000th of an inch (0.0005”). The great majority of the saw blades we sell are better than that. The great majority of the saw blades we sell do not have any measurable variance in the side clearance.

To measure side clearance you can use a side dial indicator. This is a side dial indicator and there is a little foot under the tile resting on the saw tip. Because saw tips can be tapered several different ways you need to move the side dial indicator around until you find the highest point and you use this as a measurement.

I record my readings all the way around saw blade then turn the saw blade over and record those readings. I like to start with the same tip each time. Some times a variation can be a problem with the grinding and sometimes a variation can be a problem with the tip moving. If the tip is short on one side and sticks out farther than it should on the other side it may tell you something about the wheel pressure in the grinding.

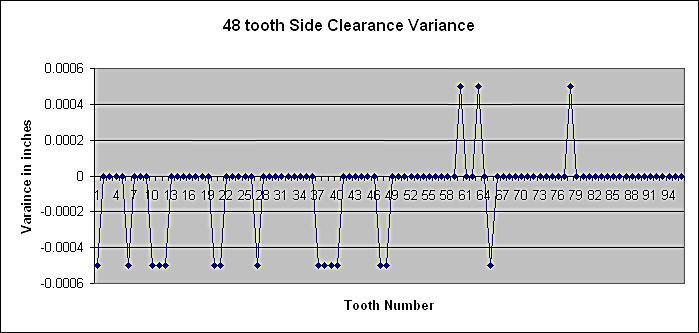

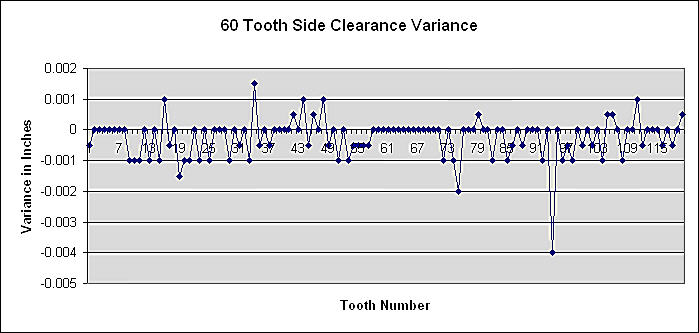

Here is the beginning of an analysis of two different saw blades. When I was done with these analyses I had 96 data points for the 48 tooth saw blade and 120 data points for the 60 tooth saw blade.

I enter this data in Excel so very easy next step is to make charts or graphs of the data.

Keep in mind that the importance is the variation of the side clearance, not the actual side clearance of each tip.

Once I have made the charts I can “File” and then “Save as” and then select ”Web Page”. This pulls the charts out of Excel and saves them as pictures in a special folder.

In the following charts you can see that the 48 tooth blade does have some side clearance variance but it is all in the range of one half of 1,000th of an inch (0.0005”).

The 60 tooth blade also has some side clearance variance but in this case it goes up to as much as 4/1000 of an inch (0.004”).

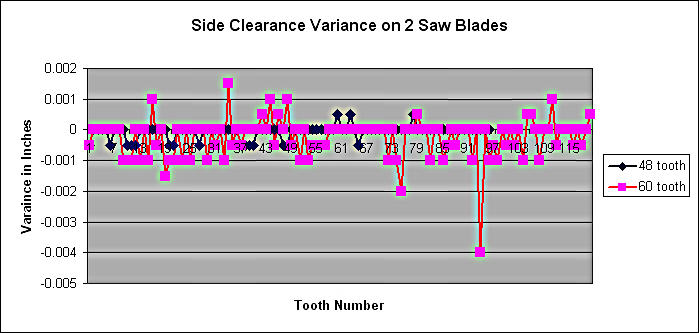

I made a single chart with the data from the two saw blades overlapping so as to better compare the difference.

Leave a Reply