Braze Analysis

Here is a braze analysis on some carbide tips that we received from Southland Tool. The tips were not staying on the saw blades, and were not pretinning.

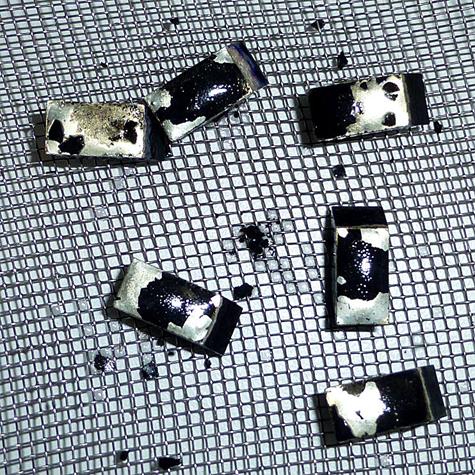

We treated the tips and they now pretin nicely. In the picture above, the carbide saw tips in the top row are the tips that were pretinned after being treated. The tips on the bottom row are show what the tips looked like before being treated and pretinned.

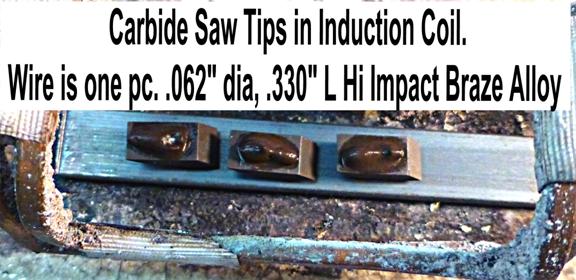

The picture above shows what we used to pretin the carbide saw tips. We used precut pieces of Braze Alloy; .062” dia. by .0.330 inches long.

The Brazing Process:

Flux Removal:

If you use enough of the right flux and do not over cook it then flux removal is easy. Here you can see that about half the flux came off just from drooping it into the wire basket.

Preparing the Steel:

The steel needs to bare, bright metal. This has been heat treated and still has the scale on it as well as a heat affected zone or layer. I worked at one tooth with a bastard file to get bright metal. You cannot get a good braze join to a scale surface.

If you can use it, a standard shape is considerably cheaper than a custom shape.

Leave a Reply