How to Braze – Underbrazing

Underbrazing

There is such a thing as underbrazing. This typically occurs with an extremely talented, experienced, conscientious brazer. I believe that sometimes tip loss is caused by not quite enough heat. I am talking fractions of a second and tens of degrees in a brazing process that usually runs around 1400° to 1500°.

Quite often, in brazing saw blades, there is a huge emphasis on protecting the saw plate from being overheated. There is also an emphasis on speed as there is in any manufacturing operation.

Braze alloy melts over a range. In addition to that, once braze alloy hits the melt point it takes a while to make the phase transformation from a solid to a liquid. If you go to YouTube you can see a Carbide Processors video that shows this.

Phase transformation is the scientific term to describe the energy required to turn a solid into a liquid, for example. If you could take a solid up to the temperature of its melting point and hold it there without putting any more energy into it then it would not melt. Once you have a solid hot enough you need to add more energy, typically as heat, to turn it from a solid into a liquid.

If you think about dropping ice cubes into boiling water you sort of get the idea. There are a lot of mechanisms in place in the “ice cube in boiling water” example but at least it illustrates the fact that the transformation from solid to liquid is not immediate.

When you braze tungsten carbide to steel you are brazing material that is about 90 to 95% ceramic to material that is 99+ percent metal. Tungsten carbide grains are a ceramic. The only metal to carry the heat is in the binder which is usually in the 5 to 10% range. Steel is typically 99% metal with a little bit of carbon. Steel accepts heat much more readily than tungstencarbide does.

When the issue of cadmium in braze alloy first came out there was an opinion that brazers were not good enough to tell the difference between braze alloys. By that time I’d been in the industry 10 years or so and I had a pretty good idea just how good some of these people were. I went to a couple of shops with a stopwatch to measure just how good brazers were. I never found out because the brazers were a lot better than my ability to measure them. Their accuracy and repeatability were just incredible.

So what I think happens with under brazing is that the brazer catches the braze alloy somewhere either in the middle of the melting range, just after the melt point or after the melt point but before the tungsten carbide has achieved full temperature.

The tungsten carbide needs to be as hot as the melt point of the braze alloy to achieve a good bond.

The only definite figure I have ever seen for just how much extra heat to use is a NASA figure that recommends an additional 50°F. However this seems to be a good figure for best practice for industry in general.

In addition tungsten carbide is often treated to make it more brazeable. Although the company that does this process insists it is not a plating process I think there could be some value in regarding it that way. As an example, tungsten carbide is not generally thought of as a ceramic but regarding it that way can help clarify a situation.

In the plating literature it is well-established that you can improve the adhesion quality of the plating by baking it after you are through with the plating.

I believe that this effect can happen to a certain extent in the brazing process of tungsten carbide.

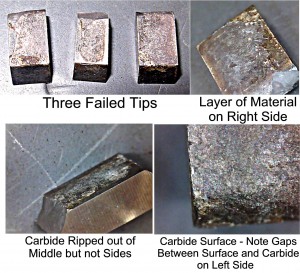

The pictures show a tungsten carbide surface. These pieces of tungsten carbide had a treatment on them to make them braze better. The reason these tips came off the saw is that the surface treatment came off the tungsten carbide taking a wee, tiny layer of tungsten carbide with it. One way the surface treatment process has been described is that it causes cobalt to migrate to the surface. If this is true then it is possible that only the cobalt immediately adjacent to the surface migrates. This could leave a discontinuity or gap in the cobalt structure between the cobalt that got hot enough to migrate and the cobalt further inside the tungsten carbide part that did not get hot enough to migrate. Fully heating the tip through would cause the cobalt to move enough to rejoin.

This theory explains the observed results. That doesn’t mean it’s necessarily true.

What is true is that shops that have had trouble with tip loss have solved their problem by using a slightly longer heating cycle. (This doesn’t always work and it is certainly not the only cause or the only solution.) It is usually described as a second or two longer. Personally I think that 2 seconds is a long time but if that’s what works then it doesn’t matter what I think.

It is also true that a heating cycle after plating can give the surface greater adhesion. Whether that is true in this application or not, I do not know but I suspect it might be.

Everything I said about how good brazers can be is absolutely true. Their ability to assess temperature and braze joint condition accurately over and over again can be truly incredible.

We Sell Braze Alloy and Carbide

800 346-8274

Tags: brazed tools, Quality

Leave a Reply