Whiteside Router Bit Progression

Whiteseide Router Bits are put to the test every year as they compete in Fine Woodworking magazine’s “Head-to-Head” Router Bit Test against many other popular Router Bits such as: Amana, Bosch, Eagle, Freud, Lee Valley, Porter Cable and many more. Every Year Whiteside Router Bits come out on top with #1 ranking for Quality and price and “Best Overall”.

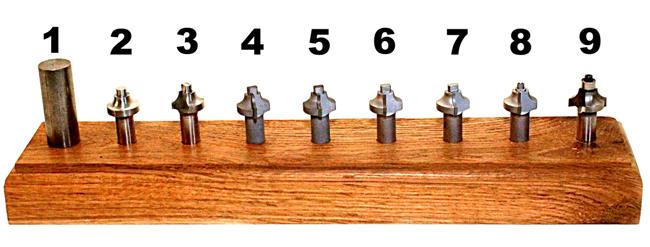

Whiteside Machine inist on excellent quality in every part of the manufacturing process for every router bit they produce. The below picture shows the progression that a Whiteside Router bit goes through during production. Whiteside Router Bits are made in the US and Start with the finest materials, a solid steel bar and the highest quality carbide and are finished with an ultraprecise finish sharpening and testing to ensure they are giving you the highest quality router bits on the market.

Whiteside Machine maintain a very strict demand for quality through the entire process of every router bit they produce. They buy the very best materials and use only the very best machines.

Whiteside Machine’s great popularity allows them to buy the finest materials in larger quantities reducing the production costs and allowing us to sell them at a great discount to you. See the steps a Whiteside Router Bit goes through from Start to finish, or shop for Whiteside Router bits. We sell the full line of Whiteside Router bits at the lowest price. If you find a Whiteside router bit at a lower price, let us know and we’ll match it.

Router Bit Progression:

1. All Whiteside Machine router bits are made from solid steel bars. Cast bodies are cheaper but not as good.

2. The bodies are precision turned on CNC lathes.

3. The bodies then go to computer controlled mills for the carbide slots

4. Large pieces of top quality tungsten carbide are brazed in using a braze alloy that is one – half pure silver. It would be cheaper without silver but not nearly as good. Then the part is sandblasted to remove brazing flux.

5. The carbide is precision ground.

6. Finish sand last and clean up.

7. Ultraprecise finish sharpening.

8. The bearing post is machined and threaded

9. The bearing is installed, tuned and tested.

One Response to “Whiteside Router Bit Progression”

Leave a Reply

Very interesting progression. No shank heat treating.

Many steps were left out as either being not interesting or as information proprietary to Whiteside.