Two Kinds of Carbide Quality

For 30 years I’ve been running across the same problem when it comes to the discussion of carbide quality.

On one side are the people that braze carbide and on the other side are people that make carbide.

The people who braze carbide want the braze alloy to stick to the carbide so that the carbide sticks to the steel tool body. If the braze alloy does not stick to the carbide then, according to the brazer’s definition, there is a quality problem with the carbide.

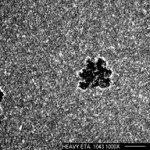

The problem comes in because the people that make carbide are concerned with how well the carbide is made and, to them, that is all internal. The carbide manufacturers want a solid, well mixed piece of carbide with no voids, porosity, binder pools or similar defects.

The brazer is not interested in the inside of the piece of carbide and the carbide manufacturer has typically not been interested in the surface of the piece of carbide.

I am a big believer in selling things that work easily and well for the customer. I also believe the supplier has an

obligation to be able to tell the customer how to use his products.

Not everyone feels this way.

We sell Carbide and Braze alloy

We do pretinning

800 346-8274

sales@carbideprocessors.com

Tags: Braze alloy, brazed tools

Leave a Reply