How To Silver Braze

How To Silver Braze

Silver brazing, as we mean it here, is joining two materials through the use of a third, dissimilar, material at a temperature above 600°F.

Silver soldering uses temperatures below 600°F and typically uses materials with 1 or 2% silver.

Silver brazing uses materials that are 30 to 60% silver and temperatures around 1,100 to 1,400° F.

An absolutely essential part of successful brazing is surface preparation. If the braze alloy does not stick to the materials then the materials will not stick together.

Before we do any brazing we test the materials involved. We take a piece of each of the materials we are trying to join and we put a little tiny piece of braze alloy in the middle of each piece. This piece of braze alloy has been dipped in flux which usually gives us enough flux for the test.

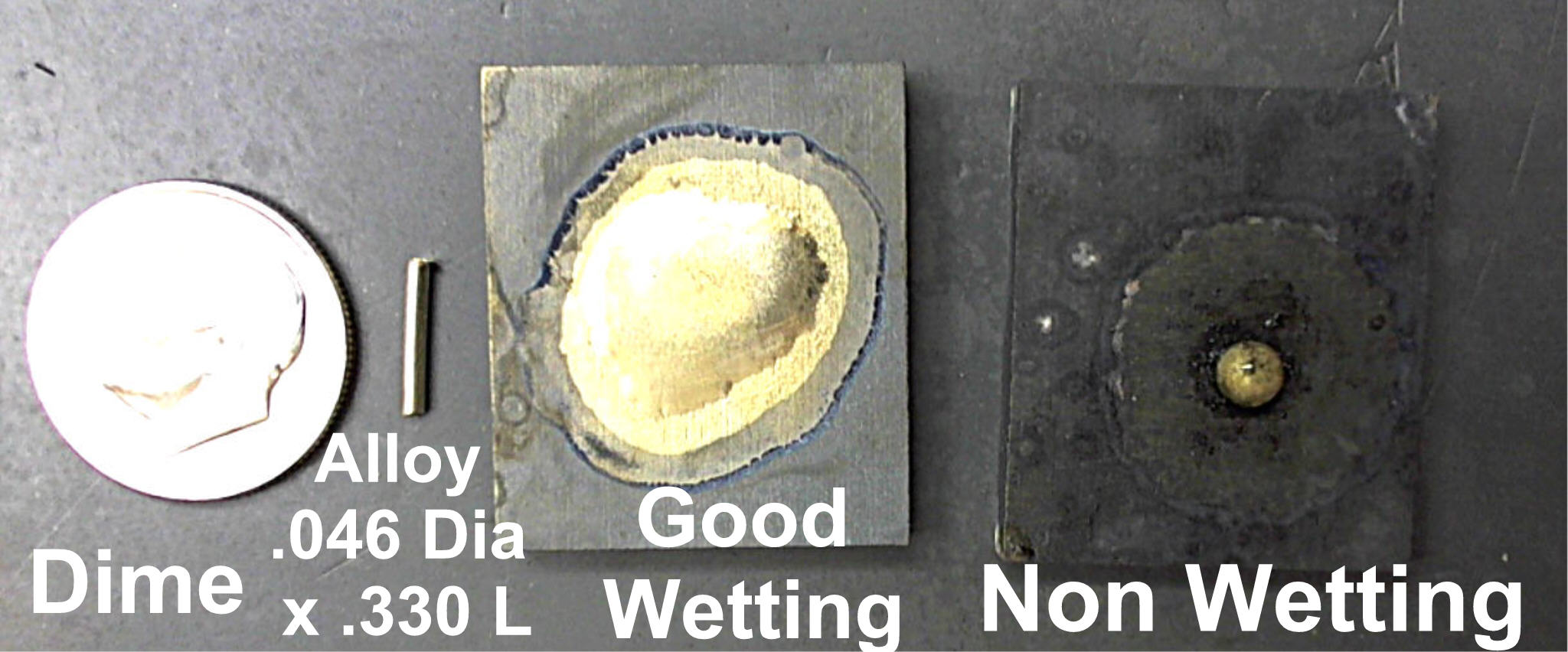

In the picture above the dime is there to show the relative sizes. We used a piece of braze alloy that is .046 inches in diameter and .330 inches long. It didn’t have to be this particular size. We just want something that is between 1/5 and 1/10 the volume of braze alloy we will use in production.

What we are looking for is wetting. Wetting is how well the braze alloy spreads across the material. This tells us how clean the material is. It also tells us how well the material eaccepts braze alloy both physically and chemically.

In the picture labeled “Good Wetting” you can see where the small rod of braze alloy flowed out to cover a much larger area. The picture labeled non-wetting shows that the surface did not want a wet at all. The wire flowed out evenly to create a pretty circular shape.

The picture labeled good wetting is almost perfect example of what you look for. The wire flowed out to cover a large surface. The braze alloy created a really good circle. (It creates a circular shape even though you start with a rectangle because the flux flows out in a circular manner and the braze alloy follows the flux.)

The non-wetting we show here is definitely bad. If you have a test shape that is much smaller than this, that is something other than circular in shape or a combination of both you may or may not get good wetting and thus a good braze joint.

Important note: Quite often people get hung up on exactly how to run this test. The standard amount of braze alloy we are supposed to use for this test is enough to create an even level across the top of the test piece to a depth of 0.001 inches. In reality we use this is a go/no-go test with a tiny piece of braze alloy. Figure out how much braze alloy you use in production and then use a piece much smaller than that. If you’re just aren’t conclusive then try an even smaller piece. This test is not designed to give quantitative information. It is designed as a simple, easy test to tell you if your material is ready to braze.

To buy braze alloy or carbide contact us, please:

800 346-8274

Tags: brazed tools

We want to braze a strip of tungsten to a piece of tool steel the tungsten strip is 200mm x6mm is it feaseable and what brazing material do we need Thanks James

Good Morning James,

Definitively make sure the material is super clean before beginning the brazing process. The cleaner the material the more stronger and long-lasting the braze joint will be. I recommend our Purified Brazing Flux. It is better than the standard black flux due to the extra processing steps of removing most of the small & large particles creating a better joint & preventing oxidation.

The 50% silver braze, CP50 is a cadmium free silver with a brazing range of 1305 – 1550. ANSI and AWS approved, you will find our CP50 braze competitively priced & sold in troy ounces in .047 or .062 thick wire.

Feel free to read our tips & trouble-shooting information for brazing applications on this webpage. Also, we have many helpful videos on our YouTube channel.

Please do not hesitate to email me with any other questions you may have at emgt@carbideprocessors.com

Jo