How To Buy A Good Saw Blade – Brazing Consistency

How To Buy A Good Saw Blade – Brazing Consistency

We sell Tenryu, Popular Tools and Everlast saw blades. There are a lot of other sawblades we could sell but choose not to.

One of the things we look for in a saw blade is brazing consistency.

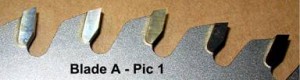

If you look at Blade A – Pic 1 and Blade B – Pic 1 you will see a definite difference in appearance. Blade A looks a lot cleaner and more consistent but I believe a great deal of that appearance is due to more sandblasting than Blade B.

Saw blades are sandblasted after brazing to clean them up and make them pretty.

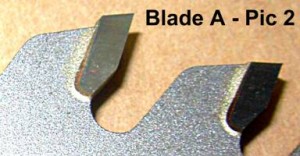

If you look at Blade A – Pic 2 and Blade B – Pic 2 you will see some very significant differences. On blade A the two braze joints are practically identical and there is very little braze alloy behind the carbide. In the picture labeled Blade B – Pic 2 you can see where there is a big gap in the braze alloy behind the tip on the left-hand tip. You can also see a hole in the braze alloy at the top of the middle tip.

The usual cause for the problem in the left-hand tip is a lack of cleanliness. If there is any oil or grease on the saw plate than the heat of brazing will turn that into carbon. The braze alloy will not flow over carbon but will flow around it instead. The major reason to be concerned with this sort of thing on a saw blade is that it indicates a lack of cleanliness which may extend to the area between the saw tip and the saw body. This means there may be areas between the saw tip and the saw body where there are gaps and thus weaker joints.

The hole in the middle tip looks round in Blade B – Pic 2. Perfectly round holes usually turn out to be part of

a sphere. This is generally caused by a gas bubble, usually zinc. Zinc is putting braze alloy partly as a temperature suppressant. It has a very low boiling point and fumes well below its boiling point much as water steams before it boils. This means it is easy to generate zinc bubbles in the braze alloy.

If you look at Blade B – Pic 3 you can see that this hole is not perfectly round but I think that’s a condition of where it is. I think I am still going to go with a zinc bubble on this one.

By comparing Blade A – Pic 2 and Blade B – Pic 2 you can see it there is a huge difference in the amount of braze alloy behind the tips. A little bit of braze alloy behind the saw tip is good because it adds additional

strength to the braze joint. However it should only be a little bit.

Braze alloy serves at least two functions here. The braze alloy holds the tip in place. The braze alloy also provide stress relief for the differences in expansion between the steel and the carbide in brazing. As part of the stress relief, or it can be considered as a separate function, a layer of braze alloy between the carbide and the tip greatly reduces impact breakage.

The thinner the braze joint, down to 0.0005 inches, the stronger the braze joint is. The thicker the braze joint, the more impact protection you have. Generally you see figures of about 0.003” to about 0.005”. You may see a specification for a thicker braze joint, particularly if you’re using larger parts.

In any case there is definitely too much braze alloy behind the tips and Blade B – Pic 2 and the brazing on the two tips is definitely different.

Conclusion:

Both saws may be perfectly good saws however Saw Blade A was obviously made with more care and more precision.

Incidentally, Saw Blade A is a Popular Tools saw blade.

800 346-8274

Tags: brazed tools, circular saws, Everlast Saw Blades, Popular Tools, Tenryu

Leave a Reply