Tungsten Carbide – Good and Bad

Good and Bad Carbide

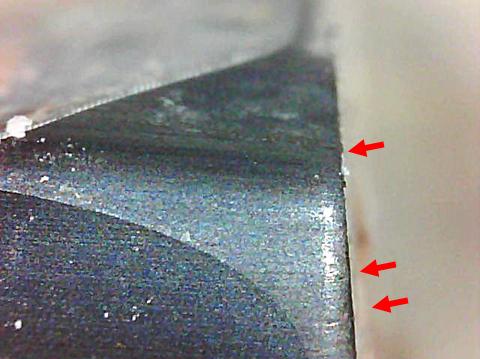

This is a piece of C-2 carbide that was used on a saw blade cutting clear, clean hemlock in a truss plant. This is a tip off of a saw blade that ran one hour. About half the tips looked like this and the other half had been either entirely beaten off or broken to the point there was only a very small chip left in the corner of a pocket.

This carbide was obviously, entirely unsuitable for the task. Furthermore I consider this bad carbide because of the extreme size of the chips. The extremely large, smooth areas indicate that a significant amount of material came off as a single chip. This is variously called flaking, spalling, chipping or something similar. Crack initiation is how easy it is to start a crack. Crack propagation deals with how well that crack travels through the material. In this case the anti-propagation properties of the material were extremely poor.

This is a piece of C-4 carbide that was used to trim the edges of gypsum board in a manufacturing plant. The gypsum contained a fair percentage of extremely small quartz particles. Quartz is very hard and actually scored the edges of the carbide. However, all the quartz particles did was create a small, appropriately sized gouge. There is absolutely no evidence of the kind of flaking that you saw in the top picture even though this is supposed to be a much harder material.

This is a piece of C-4 carbide that was used to trim the edges of gypsum board in a manufacturing plant. The gypsum contained a fair percentage of extremely small quartz particles. Quartz is very hard and actually scored the edges of the carbide. However, all the quartz particles did was create a small, appropriately sized gouge. There is absolutely no evidence of the kind of flaking that you saw in the top picture even though this is supposed to be a much harder material.

I realize these are two different grades of material in two different applications but, since we are dealing with real-world applications and have to wait for them to arise, this is actually an amazingly clear comparison.

In any case, we substituted a proper grade from a different manufacture in the top application. Instead of the saw was being very, very badly beat up after an hour we went to saws that still looked good after nine hours.

Tags: brazed tools, circular saws

Leave a Reply