How to Buy Custom Carbide Parts

Prototype Parts Can Be an Excellent Investment

We sell a great number of custom carbide parts. Some of them are made directly off of drawings. Another way to do it is to buy a few sample parts first.

If it is your first time buying custom carbide parts then getting a couple of sample parts can be a really good idea.

It adds maybe a couple hundred dollars and 4 to 6 weeks to the process. However, that is far and away preferable to opening up a box of parts made from a drawing and finding out that they read the drawing differently than you did. You can take that advice as coming from somebody has made that mistake more than once.

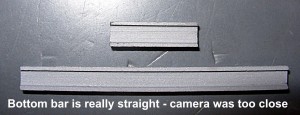

Tungsten carbide shrinks about 40% during the sintering process. The amount it shrinks is never an exact process. The tungsten carbide parts start with pressed powder. They can twist or warp or bow or otherwise move during the sintering process.

A good carbide company will be very hesitant to promise results within more than a couple thousandths of an inch although they usually do better than that.

We really believe that spending a little extra money and a little extra time to get actual physical parts can often be a great investment. You will get actual parts that you can run to your parts feeder, mate with other parts, use to build prototypes and uses reference points if you want any changes made to your production parts.

We work with a couple of companies that are really excellent at making prototype parts and would be happy to help you.

We Sell Carbide

800 346-8274

Tags: brazed tools, Tungsten Carbide

Leave a Reply