Brazing Flux

Brazing Flux

First, there is solder flux and brazing flux and they are not interchangeable. Solder flux is low temperature, below 800° F. Brazing flux is above 800°F.

For carbide brazing and similar brazing of high temperature, high silver content alloys we sell three kinds of flux.

The first kind is White Flux which is called White Flux because it is white. This is Potassium salts of Boron and Fluorine. The Boron is a cleaner and the Fluorine is an etcher.

Flux does have cleaning properties and the ability to remove oxides but it is primarily meant to intercept oxygen and prevent the formation of oxides. We strongly recommend that the parts be clean before you start to braze.

Over the years we have solved a lot of brazing problems for people around the world simply by having them switch from White Flux to Black Flux. Black Flux has the ability to stay active and keep working under long exposure at higher temperatures.

Black Flux seems to work a lot better than White Flux in many cases. The difference seems to be a lot more extreme than it should be based on an analysis of the chemistry. Many years ago I was at Cascade Southern Saw Company in Milwaukee, Oregon. They were using White Flux and were having tip loss problems. We set up a double test where we brazed some saws with White Flux and used identical parts and techniques to braze other saws with Black Flux. The White Flux saws failed because the tips came off. The Black Flux saws worked 100%. I called a flux expert at one of our suppliers and told him what was going on. He told me that the results we got were impossible. I told him I was standing in the shop watching it. He told me that he didn’t care because it couldn’t possibly be true.

We are pretty good in the lab and have been doing it 30 years. In that time I have learned that what works in the lab is only a weak indicator of how things work in the field.

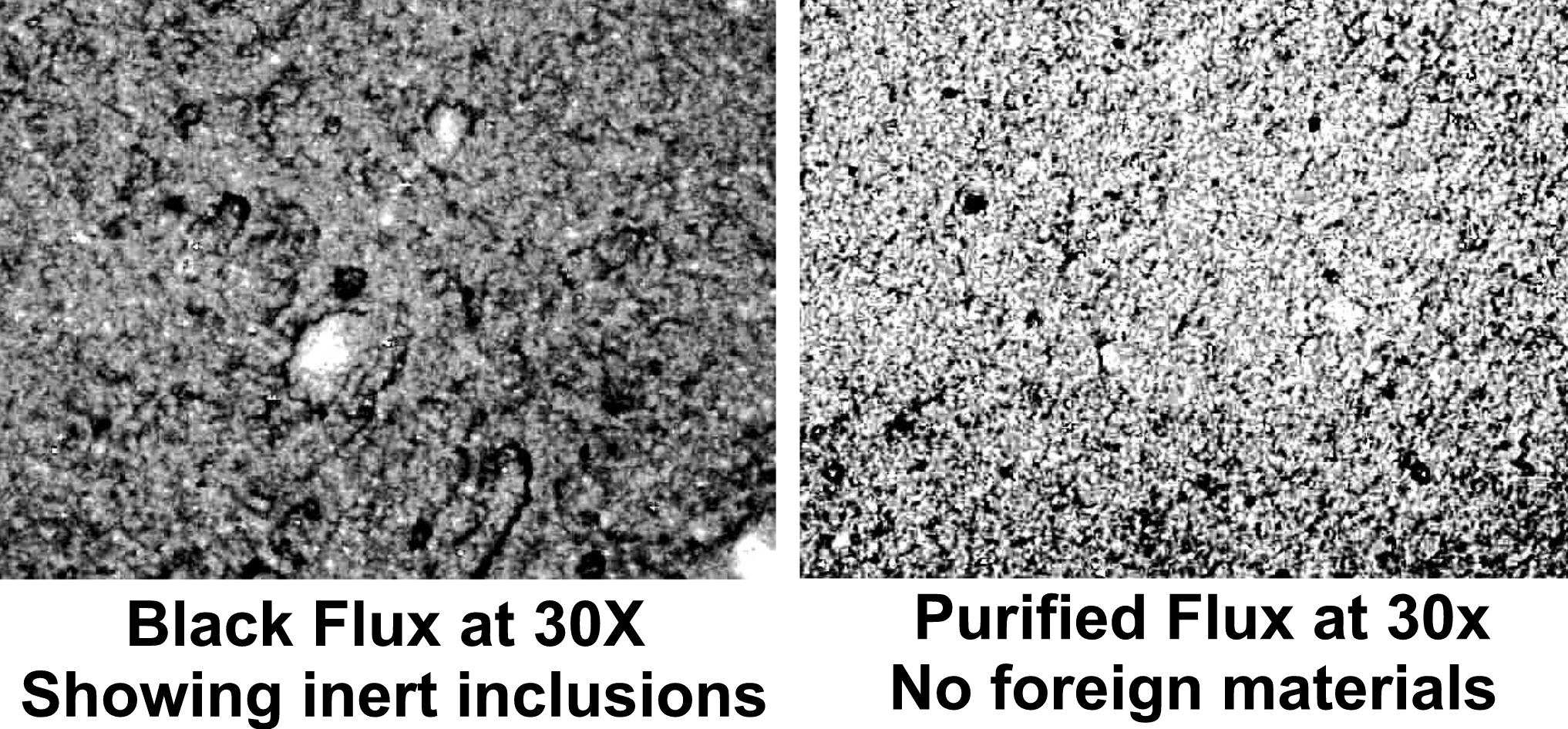

The third kind of flux we sell is Purified Flux. Purified Flux is Black Flux that has extra processing steps to remove inert materials. It gives a much stronger braze joint because it has fewer inclusions in it.

800 346-8274

Tags: brazed tools

Leave a Reply