Why Vortex Router Bits are Expensive

Vortex router bits cost a little bit more to buy but they cost a whole lot less to run.

Vortex router bits are solid carbide. What’s more they are an advanced grade of solid carbide to give maximum life with maximum toughness. The carbide blanks have been Hot Isostatic Pressed (HIPed) which is a manufacturing process designed to produce perfectly homogenous carbide parts with no voids, binder pools or similar imperfections.

Vortex router bits are ground on the finest precision CNC machines. The base price of these machines is somewhere around a half-million dollars and vortex buys the very best.

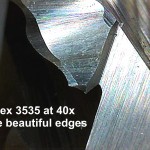

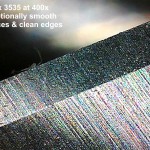

Vortex uses the very finest diamond wheels and grinds for clean edges and smooth surfaces. Grinding for clean edges and smooth surfaces means multiple passes with different grits. This greatly adds to the manufacturing time and cost but it produces tools that are sharp and that stay sharp.

You can make cheaper router bits if you grind faster and make fewer passes. However this leaves you with rougher surfaces which wear faster. It leaves you with microscopic next on the cutting edges which serve as force concentrators and greatly shorten the life of the carbide router bit.

If you look at Vortex router bits under a microscope, even a 400 X power microscope, you will see that the edges are clean and smooth. You also see that the shiny gray router bit reflects a whole rainbow of colors. This is because the grinding grooves are so incredibly fine that they actually break up white light into a rainbow effect.

Vortex router bits cost what they do because they are made to be the finest router bits in the world.

consistently. Vortex router bits run with the least downtime, the least labor cost and the least ruined material.

Buy Vortex Router Bits

Tags: Quality, router accessories, router bit, router bit set, router bits, Vortex

Leave a Reply