Overpressuring Braze Joints

Wasting Money to Make Bad Saws

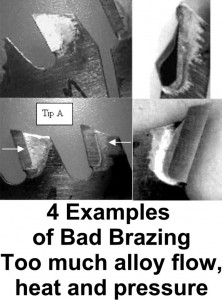

Lately I have seen a great number of saw blades where braze alloy is being wasted. Some of these are on custom-built and mil saws but it is also extremely common on factory saws from some of the biggest names in the business.

The best braze joints will have most of the braze alloy between the carbide in the steel. The braze alloy between the carbide and the steel compensates for the difference in expansion rates of the carbide and the steel. This makes the saw blade that is much tougher and helps prevent loss and breakage as well as shoulder damage. Ideally there would be braze alloy on either side of the tip running out onto the saw plate an eighth of an inch or less.

It is becoming extremely common to see saw blades were too much pressure was used to seat the saw tip. This forces the braze alloy out of the braze joint. This is a waste of braze alloy and grinding through braze alloy clogs up diamond wheels. This also greatly weakens the saw because there is not enough braze alloy between the steel and the carbide provide proper cushioning.

The tip should never be pushed into the notch. It should be placed touching the notch. This means that you want to get the saw tip and the braze alloy on the saw tip so that it is touching the steel but nothing else.

The heat affected zone should end at a distance about 0.25” to 0.50” behind the saw tip. The place where the heat

affected zone ends is often referred to as a chill line.

Heating is best done through the carbide and into the steel. The steel grows 3 to 4 times as much as the carbide and putting the heat into the carbide helps compensate for this. The steel is also much more willing to receive heat than the carbide by a factor of five or 10 to 1.

Tags: brazed tools, Brazing, Quality, saw blade, saw blades

Leave a Reply