The Horny Teenagers Theory of Brazing

The Horny Teenagers Theory of Brazing

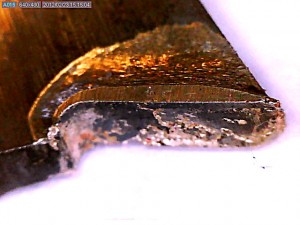

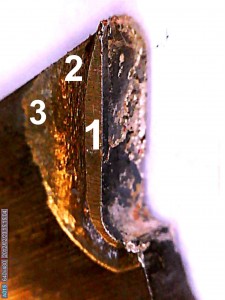

There is way too much braze alloy outside the joint or join.

I looked at eight other sawblades from different manufacturers and this is a common problem. As with any quality issue, if you do not fight it all the time it will grow until things fail.

Brazing is not a mechanical process like hammering a nail or tightening a screw.

Brazing is a chemical process.

If the steel and the carbide are both clean then they want to join. It is like two horny teenagers. Put them together and they have a really strong tendency to join. The carbide tip should just be put within kissing distance of the steel. Then capillary attraction will cause the braze alloy to flow onto the steel.

Again, as with horny teenagers, you want to stop the process when it is just a light kiss.

Back to braze alloy. Ideally you would have a little braze alloy ridge next to the tip with a slight bit of feathering onto the steel plate.

The smaller the ridge is and the less feathering you have, the better as long as you can still see a little of each.

As near as I can tell.

Area 1 is about 3 to 4 times as wide as it should be.

Area 2 is about 3 times as wide.

Area 3 should be about half as wide and immediately behind the tooth.

Don Wallinger did a great video for us.

http://www.youtube.com/watch?v=nmlj37zOvQw

Do not push the tip in. Just guide it to where it belongs.

You really, really need the braze alloy between the steel and the carbide. It relieves the stress caused because the steel grows and shrinks much more than the carbide.

Braze alloy between carbide and the steel is like suspension on an off-road vehicle. If you push it all out it is like going cross–country with no springs, no shocks, no struts, no nothing. This is a sure way to cause a lot of damage.

Braze Alloy between the carbide and steel protects the tip and the shoulder.

You should have a line alongside the tip between 0.025” and 0.075” inches wide. Ideally it should be an even line all the way around the tip. (It may be wider on the hot side and thinner on the cold side but it should always be there.)

Braze alloy outside the joint is just wasting money. It is a waste of expensive braze alloy. It is a waste of diamond wheels. The flat area just behind the tip was ground with a wheel. Braze alloy is much softer than carbide. It really gums up wheels meant for carbide.

Tags: brazed tools, Brazing, circular saws, Quality, saw blade, saw blades, sawblades

Leave a Reply