Welcome to the Carbide Processors Blog

Triton Precision Power Tools- Available Now*

Posted on Wednesday, January 7th, 2015 at 2:10 pm.

Triton Tools

Bringing your projects to life since 1976

Started in 1976, Triton Tools began in Australia at workstations and have evolved as a respected precision tool company. Triton Tools offers superior quality routers, saws, cordless power tools, and work stations.

Precision Routing Powerful Cutting

-Patented Rack & Pinion System -Powerful Motors

-Micro Winder -Precise Depth, Bevel & Alignment

-Soft Start & Variable Speed -Ergonomic Design

Cordless Unbeatable Sanding

-Lithium-Ion Power Cells -Effective Dust Extraction

-Sintered, All-Metal Gears -Belt Tracking

-Over-Moulded Grip -Lock-On Button

These are just a few of the Triton tools that we have for sale. We are currently in the process of adding the rest of the Triton line. Check our website frequently for the newly added products, discounted Triton accessories and our Contests and Promotions page.

Saw Blades for specific applications

Posted on Monday, December 29th, 2014 at 2:48 pm.

Some laminates and acrylics have a “filler” in it to save on costs. The filler is generally a clay so you are cutting through very fine rocks. That is hard on blades.

Some acrylics, laminate, plastics in general are harder and more brittle than others are. This is where a high ATB can be very helpful in preventing chipping. A high ATB is an alternate top bevel blade where the tips are sharper and more pointed . You typically have a sharper point making the initial piercing into the material and a narrower cutting edge on the sides of the tips.

Woodworker II blades are excellent general-purpose blades. They are typically very well made. Their best use seems to be in applications where they make a limited number of very short cuts. They can heat up in an application where they are cutting continuously and thus are not generally suitable for cutting materials in manufacturing applications.

Many of the special purpose blades are made for manufacturing applications. In these uses, the material is run through continuously at high speeds for a full shift with possibly breaks for lunch and coffee breaks. In this case, the different grinds really are a necessity.

Besides different grinds, different saw blades may have different carbide on them. We use a different grade of carbide on our laminate blades than we do on our general-purpose blades or on our nail cutter blades.

Our Cermet 2 grade is an extremely fine grade with a complex binder that is specifically designed to stay sharp in an extremely high wear situation such as cutting through man-made materials with clay binder where the abrasion is very high.

For general-purpose cutting, we really like our super C, which takes advantage of submicron technology to give the saw blade that is tougher than a C2 with better wear than a C3.

There are certain applications that are very hard on the carbide. If you are cutting flooring, you run into a real chance of hitting nails. Many truss applications pay their people by piece rate so they really shove the lumber through. In this case, we go with what we call our nail cutting grade, which is big grains with a lot of cobalt.

Be very careful

Saw tips do occasionally come off sawblades and carbide saw tips can break. Mostly the broken part buries itself in the wood. Occasionally the broken part lands in an eye. It has been better than a year since I received a phone call about somebody going blind because they had a piece of carbide land in their eye and I would not mind if I never got another one. It is a low probability but it does happen. It is much more likely to happen if you are using the wrong saw blade.

Bessey Aviation Snips and Compound Snips

Posted on Monday, December 15th, 2014 at 10:05 am.

Bessey Aviation Snips and compound snips combine advanced steel grades with innovative design to give you high quality cutting with less effort. Bessey manufacturers a variety of styles and steel grades of snips to give you the best cut with the least amount of effort for any cutting application. Combining core features like cutter head design, quality steel grades and intended application, Bessey’s line of compound and aviation snips are designed to get even the toughest job done.

How does Bessey give you all that cutting power with minimal effort? The cutting head and handles on Bessey’s compound and aviation snips are made separately and both the cutter head and handle are hinged. When the cutter head and handles are attached to each other, the double hinged assembly greatly increases the leverage, requiring much less effort to cut.

Bessey’s cutter heads come in 3 different styles, “Ideal Snips”, “Outline Snips”, and “Striaght Cutting Snips”. There are great benefits to each depending on your application.

Bessey’s ideal snips are a great multi-purpose snip that can cut through sheet metal as well as cutting large and small contours or radii. Whether you are cutting at the edge or at the center of the sheet, bessey Ideal style snips work for any notching -operation.

Bessey’s outline snips are the best for fine and narrow radius cuts near the edges of sheet metal. You can use the delicately shaped edge of these snips to cut extremely narrow shapes or curves without any problem.

Straight cutting snips are ideal for cutting sheets of metal at the center or the edge. The long edges of these snips make it great for cross-cutting and notching sheet metal quickly and precisely with less effort.

Bessey makes both left cutting snips and right cutting snips. The right and left cutting snips are often mistaken to be left handed or right handed cutting snips, but that is not actually the case. The Left cutting snips are actually for cutting left radii (a curve from right to left) and the right cutting snips for right radii (a curve from left to right). The Left or Right cutting snips allow you to cut inward from your wrist which is more ergonomic and much more comfortable.

Bessey understands that the service life of the cutting edge depends directly on the grade of steel used and the processing. Bessey’s high-performance aviation snips and compound snips have case-hardened High Speed Steel edges to with stand the most stringent requirements and give optimal cutting performance.

Free Bessey® Tool Winners

Posted on Wednesday, December 10th, 2014 at 3:52 pm.

I am so pleased to work for a local company who knows how to spoil their customers! The FREE Bessey® tool contest is officially over and the winners have been selected.

We love to give our customers the opportunity to try items from our new or most popular product lines. It is our way of saying “thank you” for your continued patronage. Besides, the team at Carbide Processors enjoys your comments and enthusiasm for the contests that we run. Even those of you who do not win tell us wholeheartedly how fun it is for you to participate!

Now, for the winners! Traditionally we choose 3, a Grand Prize, 1st Runner Up & 2nd Runner Up. However, the Bessey® contest is different! We are giving away FREE Bessey® tools to 4 winners! Watch our YouTube video and hear us call out your name!

If you weren’t able to participate in the Bessey® contest, no worries, you will have many opportunities in the future! Make sure you read our Blog, Newsletter, Facebook, Twitter feed and don’t forget to click on the Contests and Promotions tab!

Forget the Card, Donate Instead

Posted on Tuesday, December 9th, 2014 at 3:47 pm.

If you have ever dropped change in a red kettle outside your local business, then you have already given to the Salvation Army. Established over 100 years ago, the Salvation Army began as an evangelical movement that has blossomed into a global outreach mission. Today the Salvation Army hosts a myriad of programs and services for Veterans, hunger relief, rehabilitation, housing/homeless support, and youth programs.

Tom decided several years ago to get involved by donating baby food. A volunteer sent out a mailer to Carbide Processors to help generate donations which prompted Tom to call. He learned that baby food is in high demand along with other basic necessities like shampoo and soap. From that point on Tom decided to donate baby food and toiletries in lieu of Christmas cards.

There are many organizations that help families and individuals no matter religion, gender, economic status, disabilities or local/national borders. Why not start a new tradition by donating your time or money during this holiday season? To take it a step further, you can give all year long by volunteering at a food bank, donating to disaster relief funds, or sponsor a child at the Boys & Girls Club.

This holiday season give of our your time, give of yourself, and know that you are making a difference!

Free Bessey® Tool

Posted on Wednesday, December 3rd, 2014 at 3:18 pm.

Now that we have made it through Thanksgiving we felt it was time to run another contest for a FREE Bessey® Tool for 3 lucky winners!

***Contest begins 12/03 and ends 12/09***

For over 125 years Bessey® has built their company around their guiding principle that “One who stops improving himself has already ceased to be good.” Internationally recognized “world-class” steel makers Bessey® has grown to be an industry leader in the clamping and cutting tool industry. The 3 winners will receive their choice between: Bessey® Kliklamp Limited Edition Set of 2  The Bessey® Kliklamp Limited Edition Set has a throat depth of 80mm and six clamping capacities that range from 120 to 400mm. Made from a mix of very light magnesium, fiberglass-reinforced plastic and cold-drawn steel, the Kliklamp is lightweight but sturdy enough to get the job done.

The Bessey® Kliklamp Limited Edition Set has a throat depth of 80mm and six clamping capacities that range from 120 to 400mm. Made from a mix of very light magnesium, fiberglass-reinforced plastic and cold-drawn steel, the Kliklamp is lightweight but sturdy enough to get the job done.

OR-

Bessey® D15A Multi-Use Snip Set of 3

The Bessey® D15A Multi-Use Snip Set contains 3 compact aviation snips for long continuous, straight and curved cuts. With all the power of a full size aviation snip, this compact version gets in all those hard-to-reach places. Conveniently color coded ergonomic soft grip handles allow for maximum comfort . Made of high quality drop forged Chrome Molybdenum steel, the Bessey® compact snips are perfect for home and professional use.

Enter to win by saving 5% on your next order when you use coupon code bessey5 on orders placed 12/03 – 12/09. Your order will automatically enter you to win one of the Bessey® items for FREE! We will hold the drawing the 2nd week of December and announce the winners on our YouTube channel. Don’t miss your chance to win and experience German quality at its finest with a free Bessy® tool!

**If you would like to re-live the excitement of our last 2 contests, Woodpecker and SOG Knife give-a-ways, click on the link!

American Made Router Bits

Posted on Tuesday, December 2nd, 2014 at 1:11 pm.

The other day Tom posted an answer to a question on the SawMill Creek website. A gentleman asked his fellow woodworking community their opinion on quality router bits. Like any woodworker he needed good quality at a fair price, preferably American Made with a warranty/guarantee. Tom’s response was as follows:

“Whiteside router bits typically rate number one for both quality and value in Magazine reviews typically followed by Southeast Tools.

You can certainly buy cheaper router bits but you typically get what you pay for. Some router bits are made to be sold in big-box stores at low prices. Router bits, such as Whiteside Machine and Southeast Tools, are made to be used by master craftsman, cabinet shops, and industrial operations.

These are typically about the third router bit that somebody buys. The first is a cheap combo set people buy when they get their first cheap router. At least that is the way I did it a few decades ago. Then I went in and bought router bits individually, typically a mid-range router bit. These were okay because I was still learning. Finally, I got to a level where I could appreciate a good tool enough to see the difference it really made.

Whiteside Machine and Southeast Tool router bits cut better. One of the reasons is that they use a very fine grain carbide classified as sub-micron. Tungsten carbide is actually tungsten carbide grains cemented together with a metal. The smaller the grains are the smoother the edge can be.

Top end router bits are beautifully balanced so that they go round and round instead of wiggly, wiggly. The common term for a way unbalanced tool cut is ‘potato chipping’. When you see slow-motion videos of unbalanced tools, you can see that they move in more than one dimension. Besides going round and round they also wiggle and go up and down.

The best tools are made with a braze alloy that is about half silver. There are certainly much cheaper braze alloys. The high silver braze alloys hold the carbide onto the steel as well as providing impact protection.

A big reason that carbide gets dull and makes poor quality cuts is micro fracturing. As the parts are run, the edges get rougher and rougher. Typically, people only notice that the edges get rounder. Micro fracturing greatly increases the rate at which edges get rounder.

We sell Whiteside and Southeast. Our background is tools in industrial use. Both these companies make tools that give very long service life, allow for many resharpenings, and run reliably.

We sell everything with a 100%, lifetime, satisfaction guarantee.

Whiteside has a limit on how low a price we can charge for their tools and we charge the lowest price allowed. Southeast tool does not have a limit we can sell their tools for a little less.”

If you want more information, feel free to call 800-346-8274, email sales@carbideprocessors.com or visit our website at www.carbideprocessors.com

If you have bought or used either Whiteside or Southeast Tool router bits, please comment your experience below! Or, if you have any questions not addressed in this blog, feel free to contact us here, or by email.

Tools for Kids Program

Posted on Wednesday, November 12th, 2014 at 2:59 pm.

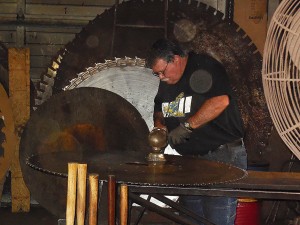

What started out as kids being interested in the old machinery at the New Jersey State Fair, blossomed into a hands-on Youth Program at NJAE&MC (North Jersey Antique Engine & Machine Club).

Kevin Adams, member and Youth Program contributor of NJAE&MC explained how the program got started:

“The youth program started because the kids in the club were interested in learning about the old machinery we had on display. It was also a way to keep them gainfully occupied during the 10 days of the State Fair. One of our first projects was the dis-assembly of a Ford 8N tractor, so the owner could sandblast and restore. The videos are linked on the web site. We have 3 lathes now that are running and we needed to have trained operators to demonstrate them to the public, the youth were the logical choice, as they are the age that most apprentices started in the old days. I started with the basics and by the end of the fair, they can make a nut & bolt. The youth are learning skills that they are using to rebuild tractors and trucks for their own use now.”

Carbide Processors, Inc. recognizes the importance of mentoring our youth and sharing the knowledge and wisdom that we have. We appreciate the skill, passion and patience it takes for teachers and instructors to pass on their gifts.

That is why Tom has created Tools for Kids, a special grant given annually to programs and schools that partner with children in teaching these valuable skills. This grant allows the recipient to choose any of our items up to $500.00 from our website.

“When we deny our youth the opportunity to explore the world through their hands, we are fostering entire generations who lack the necessary skills to effectively engage the physical world around them.”

This quote was taken from Chris Hedges’ post about his Kickstarter Program.

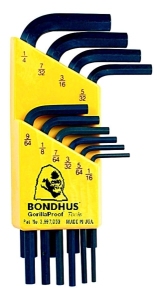

Sale: Bondhus Set for Home or Office

Posted on Tuesday, October 28th, 2014 at 11:03 am.

Bondhus Hex Keys or sometimes people refer to them as Bondhus Allen Keys should be a staple in your home or office. These versatile tools can help you put together the new furniture (Ikea), office chair, toys, router insert bits and lots of other things that require a nice range of hex keys.

There are several Bondhus sets to choose from, but my favorite set is the 10pc Bondhus 12238. I find that this particular set seems to hold the most common sizes that are universally handy for everyone.This 10pc set is offered at the lowest price you will find!

I know you can find hex keys anywhere for any price, but, I find that Bondhus is unique in their quality. Bondhus tools have long been known for their vastly superior quality, strength, durability, and resistance to rust and corrosion. Made of ProTanium High Torque Steel, Bondhus Hex Keys are up to 20% stronger and more durable than other grades of steel.

![]() Bondhus L-Keys are machined in the USA to tolerances that are the toughest in the industry and have aLifetime Guarantee. Click Here to view or download the Bondhus Technical Resource Manual for more information on how these L-keys are manufactured and tested.

Bondhus L-Keys are machined in the USA to tolerances that are the toughest in the industry and have aLifetime Guarantee. Click Here to view or download the Bondhus Technical Resource Manual for more information on how these L-keys are manufactured and tested.

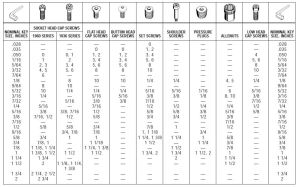

Here is a handy chart :