Welcome to the Carbide Processors Blog

Tenryu Plastic Cutting Saw Blade- Cool Customer Video

Posted on Friday, April 1st, 2016 at 12:50 pm.

We had a wonderful customer the other day in a panic! It was late in the day, and he needed a Tenryu plastic cutting saw blade-PRP-255120AB3 shipped Next Day Air to North Carolina. Our normal cut-off time for shipping is 2pm Eastern Standard time. It was after 2:30 when Whitney received his call. He needed this blade ASAP due to an issue with production and they had no back-ups!

I immediately called the Tenryu warehouse in Kentucky to see what we could do while Whitney processed his information. Without hesitation Tenryu said they would personally drop off the blade to UPS to make sure our customer would be able to receive his blade the next day. Their UPS driver had already stopped by earlier for their pick-up.

It is moments like this we are reminded and thankful for the manufactures that we work with. Tenryu is an excellent example of a manufacture who makes superior saw blades but also reflects our own business motto: The customer is always first.

Tenryu saw blades are known for their quality, super fine cuts and the price isn’t to bad either. Tenryu uses only modern, advanced grades of carbide which provides smoother faster cuts but also up to 10x that of ordinary carbide saw tips. The ATF grind is perfect for more brittle materials like plastic and acrylic. The resin filled expansion slots act as built-in dampeners keeping your cuts quiet!

The customer was so happy he promised to send us a video showing how he uses the Tenryu PRP-255120AB3 on his robots, and gave us permission to use it.

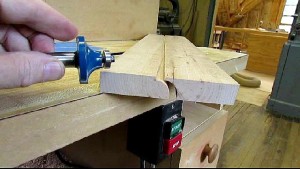

Shaping Profiles Using a Router

Posted on Wednesday, March 30th, 2016 at 1:42 pm.

Routers produce accurate & predictable results on straight, angled, or circular edges & on inside/outside curves. Routers can do so many things: molding, grooving & rabbeting planes and scratch stocks. The Triton MOF001 & TRA001 routers are perfect for routing shaping profiles. Offered in two sizes, the MOF001 is more compact with a 2 HP motor making it more than capable to handle any job, but light enough for hand-routing. The Triton TRA001 features 3-1/4 HP and has a high range of RPMS: 8,000 – 21,000.

Triton routers are quick to set up, and leave a smooth, professional finish thanks to the variable speed motors. Different materials & techniques require different routing speeds. Although running at top speed gives the best finish for general wood & plastic laminate work, it also has a greater tendency to burn the wood than slower speeds.

Types of Router Bits Needed

For general edge routing the most common shapes you will see are: flush trim, chamfer, roundover & rabbet. Using carbide-tipped router bits versus high speed steel pays off in the long run. High speed steel dulls very quickly and if overheated can lose its temper and become to soft to use. Tungsten carbide tips cut easily through hard materials and stay sharper much longer,especially when used on particle board & plastic laminate. The carbide bits will eventually start to dull, but you can have them professionally sharpened. Carbide Processors offers sharpening services for router bits and saw blades.

Always choose the shortest router bit you can. The longer the cutting edge, the more potentially damaging vibration & deflection the tool suffers. Using the largest diameter shank your router will accommodate will help for similar issues. Use caution when using very large diameter bits for panel raising or shaping thick materials that require slower speeds. At high speeds these bits can cause dangerous kickback, and are subject to severe stress that leads to breakage.

If a piece of a bit breaks off, it can be thrown out with great force. To reduce strain and get a better finish with larger bits, remove as much waste material as possible beforehand by chamfering, using a smaller diameter bit or take multiple shallow passes.

Routing Technique

Most often you will get better results if you don’t try to remove all the waste in one pass. It is better to take several shallow cuts instead, lowering the bit a little each time and finishing up with a very light cut to assure a smooth surface.

*Do not change the cutting depth by adjusting the bit shank in the collet. Adjust the router base to set the cutting depth (the Triton plunge route is makes this a lot easier!)

Feed direction is very important when routing. Always feed the router in a direction opposite the way the bit is rotating. Keep a firm grip on the router to maintain control at all times.

As versatile as the portable router is, it can be even more helpful by mounting it upside down in a router table. It then becomes a stationary machine, a small shaper, that can be used with a variety of fences, hold-downs & stops. The large diameter bits previously mentioned are unsafe to use freehand, but secured in a router table they can greatly extend your range of joinery & shaping choices.

Rip Cutting Using a Table Saw

Posted on Wednesday, March 23rd, 2016 at 12:11 pm.

The process of rip-cutting is often referred to as cutting parallel to or parallel with the grain. This is true when it comes to solid wood but when ripping plywood you’ll find yourself ripping across the surface grain. Perhaps a better way to describe rip-cutting is- the process of cutting stock to width.

Rip-Cutting Using a Table Saw

The most convenient and accurate way to rip lumber and sheet goods is by using a table saw with a good quality ripping blade. We stock several high quality ripping blades with different tooth configurations for the best cut on your application. Also make sure the rip fence you’re using is parallel to the blade and at a right angle to the table. Squaring up the fence can be tricky due to the poorly made fences that usually come with some table saws that you buy. You might want to strongly consider purchasing a calibrated fence that is more sturdy, adjustable & accurate like the Incra LS-Positioner or the Incra WONDERFENCE. Incra also offers complete joinery systems that include a base mount, rip fence, shop stop, right angle & 51 templates.

Making Rip Cuts

It is a good idea to always make a test cut on a piece of scrap before cutting your stock. Begin by setting the rip fence so the distance between its inner face and the teeth of your saw blade is equal to the width you’re after for your work-piece. Use a rule to set the distance rather than relying on calibration marks on the front of the table. Once the blade is positioned correctly, lock the fence in using the locking handle. Set the blade height so it extends no more than about 1/2 inch above the surface of your work-piece. Make sure you stand to the side of the blade, not directly behind it. This will prevent you from getting hurt if the board gets kicked back when ripping.

Push the board with your right hand while guiding it firmly against the fence with your left. Keep firm control of the work-piece while cutting until it is well past the blade. Once you have finished your pass, turn your saw off to retrieve the board to check the cut you made. Measure the scrap piece to verify it is exactly the right width you need.

*One important point to remember is to never let your fingers get closer than about 6 inches from the blade. Also, never let your hands get directly behind the blade or they could get pulled into it in the event of kickback.*

*Another safety option is to purchase a Micro Jig pushblock. It works somewhat like a feather board plate, holding the cut-off piece in its original position through the entire cutting process.*

To rip a narrow board, use a push stick rather than your hand to feed the board. A featherboard, like Woodpeckers VPFB, clamped to the saw table will press the stock against the fence & allow you to keep your left hand away from the blade. Hold downs like Woodpeckers Knuckleclamp, can be clamped to the rip fence to prevent the stock from bouncing or chattering as you feed it. Make sure featherboards and hold downs are not pressed too tightly against the stock.

Tips & Tricks

- Long boards- Tip the back edge of the board up so it is slightly higher than the saw table. Doing this will press the leading edge of the board down on the saw table. Lower the back edge of the board as the cut progresses.

- Ripping Sheet goods- Full sheets of particle board, plywood or other sheet goods can be ripped effectively using a table saw if you position a sturdy table on the out-feed side of the saw at, or just below the table surface. Some wooodworkers prefer to cut the sheets down to size using a circular or panel cutting saw first.

Not quite sure what the difference is between ripping & crosscutting? For more information read our blog here.

“Tools for Kids Program” Leads to World Championships

Posted on Thursday, March 10th, 2016 at 11:26 am.

Carbide Processors, Inc. recognizes the importance of mentoring our youth and sharing the knowledge and wisdom that we have. We appreciate the skill, passion and patience it takes for teachers and instructors to pass on their gifts.

That is why Tom has created Tools for Kids, a special grant given annually to programs and schools that partner with children in teaching these valuable skills. This grant allows the recipient to choose any of our items up to $500.00 from our website. Please contact Jo at emgt@carbideprocessors.com if interested in applying for this special grant.

One example of the influence of this grant is the VEX program at a middle school in Maryland. Elizabeth Dodson describes the VEX program as this:

“The VEX Robotics program, which is a part of the REC Foundation (http://www.roboticseducation.org/), is an incredible program that fosters STEM in the community, inside and outside of schools. The obvious aspects are engineering and programming but it also teaches kids to present their work to adult judges and to learn to communicate with their peers, since the kids have to figure out how to work together (and against each other!) on the competition field.”

We are honored for the 2nd year in a row to sponsor needed items such as hex keys, (like the Bondus 5/64″ hex keys, or the Bondhus 3/32″ hex keys), safety glasses, (Edge Eyewear) and calipers (Oslun digital calipers). The Vex teams’ motto ‘Nothing But Net” helped lead them to the World Championships hosted in April 2016.

Setting Up Your Shop- Choosing Your Space

Posted on Wednesday, March 9th, 2016 at 1:32 pm.

Attic Shop

Woodworking virtually demands its own space. The materials needed are bulky and the necessary power tools are fairly big. And since most projects are completed over a period of days, weeks and months (maybe even years), they’ll need a place to reside.

Without doubt, the best shop is a large, separate building with plumbing & heat. However, establishing and maintaining such a shop requires money and space that most people don’t have. So look for realistic alternatives that you can afford.

Another important consideration should be taken for those around you! Not everyone enjoys the sound of noisy tools that generate a lot of dust. Confining the mess and noise to a dedicated area will make everyone happier, including you.

The two most common shop locations are the basement and garage. Other dedicated spaces have been spare rooms , attics & even closed-in porches.

Basement Shop Garage Shop

Their are some important factors to keep in mind when assessing potential shop areas, or considering upgrading or remodeling your current shop.

Space needs: You’ll want to have enough space to maneuver full-size sheet goods and boards that are 8 feet or longer. Ideally this means a large enough area that you can feed large stock into a stationary tool with enough clearance on the infeed & the outfeed side.

Access: Convenience is key! You’ll need a convenient entry/exit point so you can carry materials into the shop & take completed projects out.

Power: You should never run more than one tool at a time (except a tool & a shop vac or dust collector). Nevertheless, you’ll need several accessible outlets.

Light: Adequate light is essential for doing careful, comfortable, accurate & safe work. You’ll need a good overall light (a combination of natural & artificial light sources is best) as well as some movable lighting.

Ventilation: To help exhaust dust and fumes, you need a source of fresh air & dust collection. Depending on where you live, year-round shop use will likely require a means of heating and cooling.

Take a few chances to see what works well for you, your family & neighbors. Don’t forget, the more pleasant & comfortable your shop is, the more likely it is you will spend time in it.

FREE Microscope for Your Cell Phone- ***Limited Quantities***

Posted on Tuesday, March 1st, 2016 at 1:42 pm.

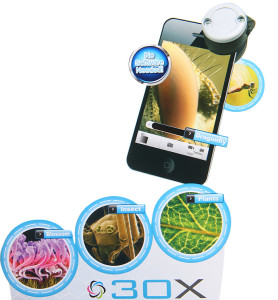

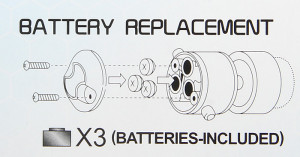

Sometimes we find really neat, fun stuff that we will never sell. Not because we don’t like it, but due to our own high standard of quality. Tom found this mini microscope that fits on any cell phone. The best part, not having to download any software to use it! Most of the time when you purchase some new type of fun gadget a very long & tedious download is necessary. However with the Cellular Phone Microscope Science Investigator, just take it out of the box, and attach it to your cell phone.

The magnifying device needs to be placed directly over your cell phone lens. Once it is securely in place turn your phone camera on and zoom up to 30X magnification using your phone’s camera digital zoom. You can see all kinds of fun things up close: flowers, rocks, plants or anything you need to zoom in close to see. The recommended age for this item is 8+.

Tom ordered a couple for fun and decided to give me one to try out. It slid over my phone very easily it was not complicated to adjust. My son (7) thought it was really cool because he could look at dead bugs close up!

We have 3 of these and would like to give them away to those who want to have a little fun or just need help in seeing. We will pay for the shipping & handling. This offer is good only while we have them!

Please respond to this blog, or email Jo at emgt@carbideprocessors.com.

Super Scraper- New Favorite Tool- South Main Auto Repair

Posted on Monday, February 15th, 2016 at 11:24 am.

Wow, the Super Scraper has done it again! I can’t think of a more universal tool then the Super Scraper. A Made in the U.S.A. multi purpose carbide edge( our Super C carbide) scraping tool designed for use by mechanics, machinists, welders, hobbyists, and all types of do-it-your-selfers!

Here is another testimonial of the SS5 Super Scraper’s superior ability to handle any job by South Main Auto Repair!

Watch Jeremy the diesel mechanic’s video on the SS1 Super Scraper!

The Super Scraper is even recommended by the ToolGuyd, read his review here.

The Super Scraper is available in 3 sizes. The 1- 1/4″ Super Scraper and 2″ Super Scraper come with an ergonomical, 100% wooden handle that is designed to fit comfortably and give a nice no-slip grip. The 5/8″ wide Super Scraper blade is perfect for smaller jobs & to fit into tighter places. Fitted with our own custom micrograin Super C grade carbide, the Super Scraper was built to last for even the toughest jobs!

Use the Super Scraper to Remove:

- Rust

- Paint

- Metal Buildup

- Varnish

- Glue

- Concrete and More!

Lifetime Guarantee:

We are so confident in the quality of the Super Scraper, it carries a Lifetime Guarantee to be free from defects in workmanship and materials. (Warranty is void if the tool is altered in any way or shows signs of abuse or misuse.)

Free Sharpening for Life:

We will resharpen any Super Scraper free of charge, you just pay the shipping & handling.

Klein Tools- Made in the USA Professional Tools

Posted on Wednesday, February 3rd, 2016 at 12:43 pm.

Since 1857, Klein Tools has manufactured tools with the highest quality materials, superior workmanship all made in the USA. Klein Tools continues to invest in U.S. manufacturing and is committed to maintaining its place as the #1 choice for electricians (Electrician’s Tool Guide & Review). Klein is the only major tool manufacturer worldwide focused on electrical and utility applications. No other manufacturer of hand tools and related products used in electrical applications makes more items in America than Klein Tools.

In October, 2015 Klein Tools was given four Pro Tool Innovation Awards for their products. A panel of judges, representing tool professionals from across the United States weighed in on entries from top global manufacturers and Klein Tools was selected from among 160 submissions.

Popular Mechanics touted the Klein Adjustable Screwdriver as the “Best New Tool“. The adjustable length goes from 4″ to 8″ and is held in securely with a locking collar. The unique shaft is double-ended; One side has a #2 Phillips head, while the other has a 1/4” straight head.

Klein Tools is best known for their model 201 Lineman’s Side Cutting Pliers, a design featuring heavy-duty jaws with angled facets. This design practically defined the term “lineman’s pliers” especially given the Klein logo in 1912. Other manufactures at that time referred to their own brand of pliers as having a ‘Klein Pattern”.

We have just launched our Klein Tools line last week and are still in the process of adding more products. Feel free to contact us with any questions you may have, or tools you may be searching for. Please email emgt@carbideprocessors.com or call us at (800)346-8274.

HTC Tool End Mills and Burs

Posted on Thursday, January 28th, 2016 at 1:10 pm.

We are excited to announce a new line of cutting tools to our standard cutting tool line. With the addition of HTC Tool End Mills, we now have over 23,000 products and are continuing to grow.

HTC Tool manufactures all of their cutting tools right here in the USA in their own plant in Fraser, MI on State-of-the-art machinery. They have 170 CNC Machines and have recently acquired 4 new Platit coating machines to meet an increase of demand and supply quality tooling even faster. With recent addition of buildings, employees and State-of-the-Art Machines, HTC can now produce 28.7% more tools than the previous year, ensuring the tool you need is always ready to ship right to your door.

With their latest expansion, HTC Tool can efficiently coat any tool in your choice of TiN, TiCN-HTC Progressive Coat, AlTiN-HTC HArd Coat, or ZrN, so that you have just the right tool for your specific application.

HTC Tool is opened 6 days a week in order to increase production and to ensure the tool you need is always on the shelf, ready to ship. All HTC End Mills are made from quality carbide with strict tolerances and manufacturing guidelines to ensure the highest quality and longest tool life.

We’re both proud and excited to offer such high quality and American Made End Mills and burs to our line of quality cutting tools. We are confident that anyone who uses our HTC Tool End Mills will agree that they are quality tools that will get the job done.

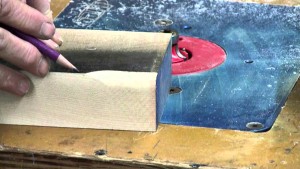

Roundover Bits- 101

Posted on Monday, January 25th, 2016 at 2:48 pm.

Roundover Bits

Roundover bits are used for outer edge shaping, moldings, picture frames, etc. These bits typically include a bearing and are not suitable for plunging directly into the surface of a panel. Rounding an edge makes your work more durable & appealing to the eye because it won’t show dents, splinter, or lose its finish as easily as a sharp corner.

Radius

Roundover bits are generally classified according to the radius they cut. For example, a 3/4″ roundover bit cuts a 3/4″ radius. To determine the radius of a roundover bit, measure either of the dimensions shown in the picture.

Roundover Bit Set-Up

After mounting a roundover bit in a router, adjust the bit up or down so the bottom of the concave cutting edge aligns flush with the router base or the surface of the router table. You can use a flat block of wood to check your adjustment.

Before cutting your stock, test the cut on scrap piece. If the bit extends too far, it will cut a slight ridge into the work piece surface, called a fillet. If the bit does not extend far enough, it will cut an incomplete radius.

How to add a fillet

By extending the bit slightly, you can cut a round-over with a fillet like the one shown in the picture.

Change the Bearing to Make a Beading Bit

You don’t have to buy beading bits, save $$$ by purchasing different sized bearings for the same results! To change bearings, simply loosen the set-screw on the bearing with a hex key.

Buying Roundover bits

Roundover bits can be purchased individually or in sets. The sets vary in profiles; you can purchase a set that includes straight, rabbeting, cove, up-cut spiral as well as sets that have only roundover bits. Some of our Whiteside roundover sets even include the bearings needed for beading profiles. .